Manufacturing USA is Reinventing the PPE Supply Chain in the Face of COVID-19

Manufacturing USA is Reinventing the PPE Supply Chain in the Face of COVID-19

When the COVID-19 pandemic hit, there was an initial shortage in the personal protective equipment (PPE) desperately needed for medical caregivers as well as the general public to curb the spread of the disease. Manufacturing USA reports that with most of the world’s PPE production is in Asia, U.S. manufacturers were not able to quickly adapt to the uptick in demand for PPE. The ASME Manufacturing Public Policy Task Force also recognized the challenges facing U.S. manufacturers and has since released a White Paper on The Hazards of Global Supply Chains.

In a recent report by Manufacturing USA, the challenge of reinventing the supply chain in the face of COVID-19 are clearly laid out. First, the Manufacturing USA program had to identify “early workarounds” in PPE production, which lead to the Manufacturing x Digital Institute (MxD) to create instructions for manufacturers to make DIY face shields. MxD provided incentives for its 300 members to manufacture these face shields, exemplifying just how well-positioned the Manufacturing USA program is in being able to influence the U.S. manufacturing sector.

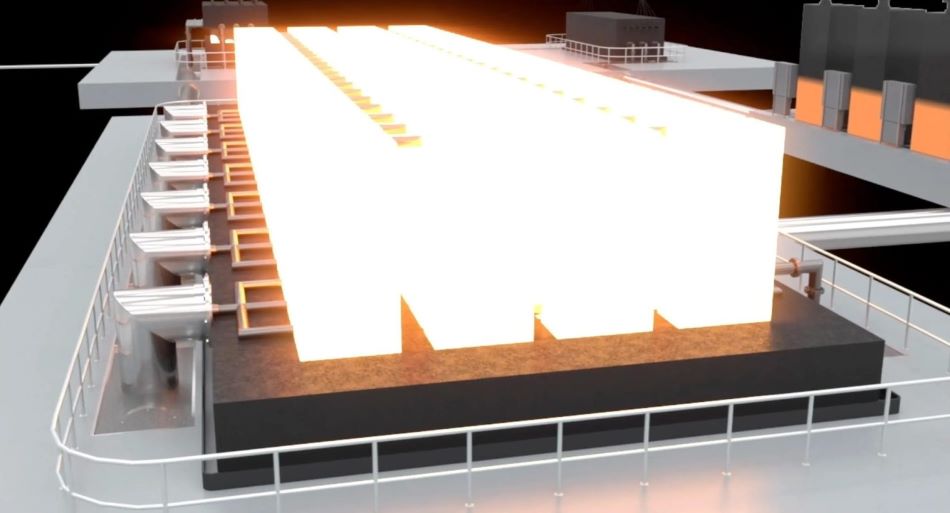

Second, while manufacturers had to quickly adapt to meet the demand for PPE, they were forced to meet new legal compliance standards that would have significantly slowed the process if not for Manufacturing USA’s ability to guide its members through the transition. The Advanced Functional Fabrics of America (AFFOA) Institute actually created a regional network of testing locations to meet the new demand for quick compliance, which allowed manufacturers to produce N95 masks much more quickly than they would have otherwise been able to.

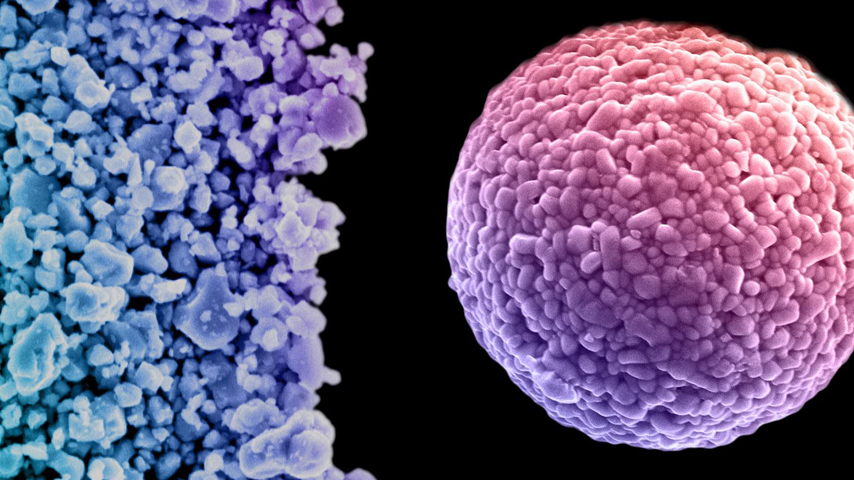

Now, the Manufacturing USA network of Institutes is looking towards the future. Many of the Institutes are engaged in developing “next-generation masks” and in establishing a pipeline necessary for the manufacturing of such PPE. The COVID-19 pandemic led to great obstructions in the global PPE supply chain, which caused the U.S. to take a look at its domestic capabilities and identify areas for immediate change as well as how to be better prepared for future global disruptions.

“The work on reinventing the PPE supply chain demonstrates the value of the large-scale support for innovation that Manufacturing USA is providing to the U.S manufacturing sector. Through public-private partnerships, last year the institutes leveraged $133M in federal funds to attract $355M in state and private investment, worked with 1,900 member organizations to collaborate on over 560 major research and development projects, and partnered with educational organizations to teach thousands of people about advanced manufacturing technologies via workshops, courses, internships, and apprenticeships.”