Advances And Challenges Of Regenerative Medicine

Advances And Challenges Of Regenerative Medicine

ASME HOSTS CONGRESSIONAL BRIEFING HIGHLIGHTING ADVANCES AND CHALLENGES FACING THE FUTURE OF REGENERATIVE MEDICINE

On April 10, ASME sponsored a briefing on Capitol Hill in partnership with the House Manufacturing Caucus to highlight the challenges facing regenerative medicine. Organs on Demand: What’s Stopping Us from Made-to-Order Tissues and Organs brought together leaders in the field of regenerative medicine working to take this technology to the next level. The purpose of the briefing was to educate members of Congress and congressional staff on the opportunities advances in this field have created for the future of modern healthcare, as well as some of the challenges preventing these opportunities from becoming a reality.

Dean Kamen, Executive Director of the Advanced Regenerative Manufacturing Institute (ARMI) kicked off the event by providing the keynote address. He discussed the work ARMI is undertaking, with special attention paid to ARMI’s new tissue foundry. Currently, patients in need of an organ transplant are limited in their options. They must wait for a suitable donor to come from another patient, after which they will spend the rest of their lives taking a cocktail of immunosuppresants to ensure their new organ is not rejected. But in the future, what if it were possible to simply grow a new organ from the patient’s own cells? This is what lies at the heart of ARMI’s tissue foundry. Kamen explained that the goal of the foundry is to create a space where new organs can be manufactured from a patient’s own cells, thereby eliminating the need to take an organ from another patient, and the myriad of immunosuppressant drugs the patient is required to take.

Kamen also explained that the regenerative medicine field is new and continuously evolving. There are very few large players in this market with the majority of the work being carried out by small, innovative companies. At the current time, the majority of the research in regenerative medicine is taking place on a small scale in laboratories. Looking to other manufacturing fields outside of healthcare, it is easier to identify major players that are pushing technology forward. But the field of regenerative medicine, while small with relatively few players, is moving the needle on technological innovation and healthcare at a rapid rate. In discussing the work of ARMI and how regenerative medicine fits into the framework of American additive manufacturing, he noted, “We’re small compared to them [other manufacturing industry players], but we’re big compared to nothing.”

Following Kamen’s address, David Vasko, Director of Advanced Technology at Rockwell Automation spoke to the audience about some of the major obstacles standing in the way of creating tissue foundries and bringing regenerative medicine to the commercial market. Currently, these technologies take place on a small scale in a laboratory. This is expensive and hard to scale up due to the current regulatory climate and amount of time the technology takes. Introducing automation into the mix could have a significant impact on how regenerative medicine would look in the future. Vasko highlighted this through the analogy of cookies in a bakery versus a factory. Currently, producing new tissues is akin to a baker hand-crafting an individual artisan cookie. It is time consuming and expensive. He compared this with mass produced cookies that are produced at a large scale through automation in a factory. These cookies are produced in bulk at a much quicker rate for significantly less cost. The challenge now is how to get from the artisanal stage to the factory stage without sacrificing quality.

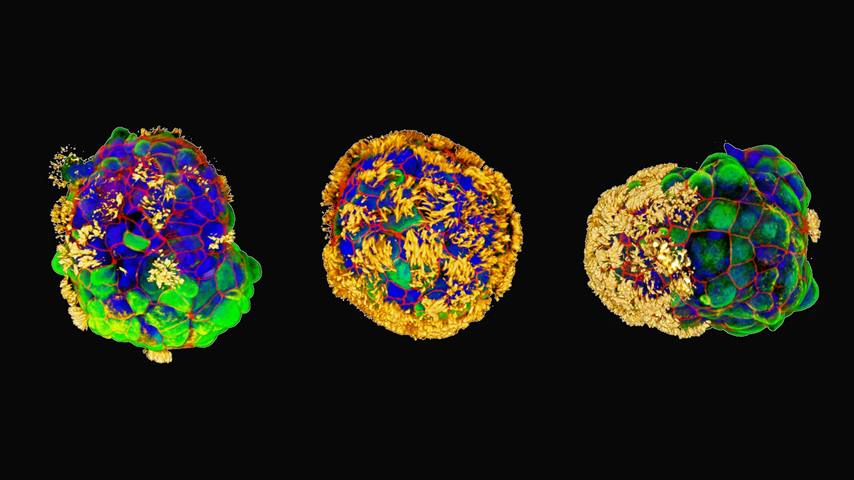

Jon Rowley, Chief Product Officer of RoosterBio built on the premises Vasko discussed. Rowley explained that cells are the foundation of regenerative medicine. But one of the biggest factors preventing regenerative medicine from large-scale commercialization, is the cost of cells. Currently the technology associate with regenerative medicine is very expensive. It can take millions to billions of cells to construct a new piece of tissue. Rowley noted that for tissue engineering to become commercially viable, the cost of the raw materials must lower and consequently “as costs get reduced, sustainable businesses become a reality.”

Building on this, Rowley then switched gears to provide a different perspective. As important as it is to have reasonably priced raw materials, it is also essential that the most efficient manufacturing method be employed. What if, he argued, all the previous innovations in regenerative medicine that had failed for being too expensive had actually failed because they did not employ the most efficient method of manufacturing? “Is it possible that there were unprofitable drugs developed over the last 20 years that if put into today’s Manufacturing Platforms, could be the basis of new profitable businesses?”

Rounding out the panel was Claudia Zylberberg, chief executive officer of Akron Biotech. Zylberberg broke down for the audience how cell therapies work, starting with blood collection and processing, all the way to end stage treatment. She also provided the same explanations for tissue engineering, building off of Rowley’s discussion in which he showed how cells and cell therapies are the foundation of tissue engineering. Zylberberg also took things to the next level for the congressional staff in the room, highlighting specific organizations dedicated to regenerative medicine at a state level. Through Zylberberg’s presentation, the state-by-state disparities in funding was made starkly clear. California and Texas are the leaders in state funding for regenerative medicine, both providing $3 billion a year to their organizations.

Zylberberg also provided a macro-level view of funding for regenerative medicine, highlighting that in 2018, nearly 1000 companies were active in the regenerative medicine space, 50 percent of which are American. These companies raised $13.3 billion, a 73 percent increase form 2017. By 2024, the regenerative medicine market is expected to reach $40 billion.