ASME Hosts Congressional Briefing Highlighting Advances in Bioengineering

ASME Hosts Congressional Briefing Highlighting Advances in Bioengineering

ASME recently hosted a congressional briefing on Bioengineering: A New Frontier in American Manufacturing. The event featured keynote speaker Dean Kamen, Executive Director of the Advanced Regenerative Manufacturing Institute (ARMI)/BioFabUSA, a Manufacturing USA institute focused on regenerative medicine. Kamen designed several major innovative technologies in the bioengineering sector, including the first portable insulin pump, the iBot all-terrain wheelchair, and the Segway.

Kamen kicked off the briefing with the analogy, “science is a goldmine, engineering is how you get it out of the ground and make it valuable.” He discussed the mission of ARMI, explaining that it filled a role nobody else was tackling by focusing on engineering and scale, rather than basic research. Kamen explained that the future of biomanufacturing is the manufacturing of organs such as kidneys to replace those no longer functioning, rather than chronically treating them. This will save the government a lot of money, and have a correspondingly immeasurable impact on the cost of healthcare for all Americans. Looking to the future, Dean stated he hopes to turn Manchester, New Hampshire—where ARMI is located, along with several other biomanufacturing and advanced manufacturing companies such as Kamen’s other company DEKA Research and Development—into an “east coast version of Silicon Valley for organ reproduction,” and “transition to a world where regenerative organs are as common as vaccines.”

Following Kamen’s presentation, Senator Shaheen provided remarks, expressing her excitement that the Department of Defense (DOD) played an integral part in helping ARMI get off the ground, further noting that DOD is a key player in advancing new technologies. The innovative new technologies ARMI is developing have immeasurable potential, including the ability to bring relief to patients on the organ donor list. These technologies also reinforce the major impact that science has on daily life, and the need to continue supporting our science agencies. Senator Shaheen also touched on the dearth of qualified scientists moving into the bioengineering field, explaining that the University of New Hampshire system is closely engaged with ARMI, but more must be done to encourage young people to pursue bioengineering. In closing, she conceded that the current costs of higher education are a barrier to prospective students.

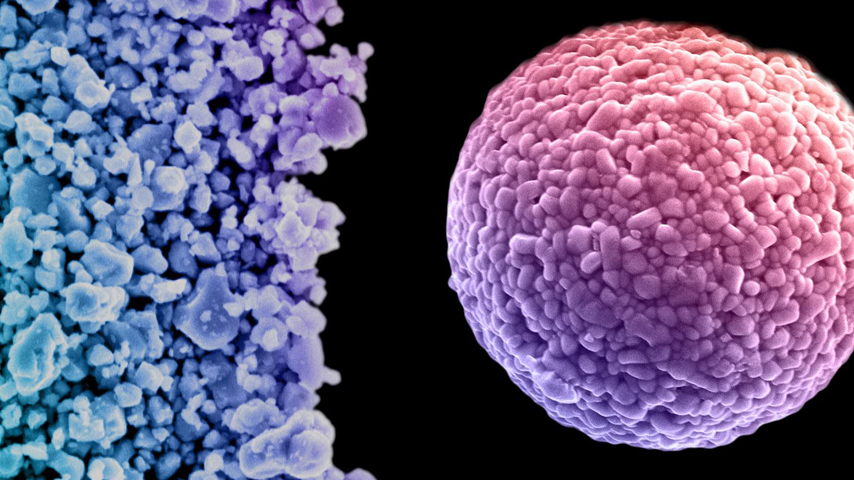

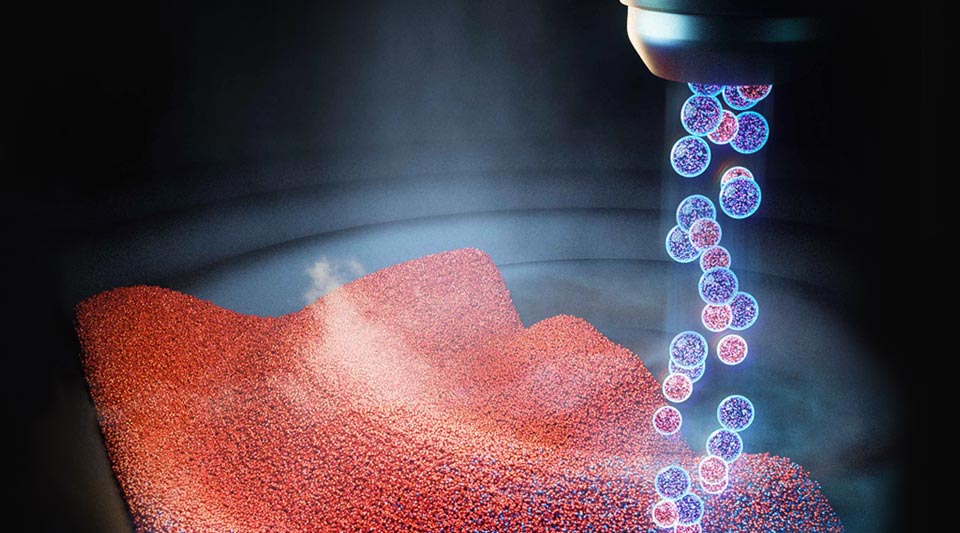

Following the Senators remarks, Michael Golway, President and CEO of Advanced Solutions Life Sciences, discussed some of the groundbreaking technology his company is working on. Advanced Solutions is a biomanufacturing company with locations all over the country, including their newest location with ARMI in Manchester, NH. He explained that the work of Advanced Solutions is a “very small piece of the big puzzle” Kamen discussed in his keynote address. Golway shared several videos with the audience of the BioAssemblyBot (BABs), a 3D bioassembly technology platform that is also the world’s first human tissue printer. He explained that BABs moves like an arm and can also control workflow. Additional tools can also be attached to the arm for further functional variation. In addition to BABs, Advanced Solutions is working on Patented Angiomics, a technology they have developed in conjunction with ARMI that harvests blood vessels from fat cell tissues, which then undergoes new angiogenesis.

Rounding out the speaker panel was Jennifer Hagan-Dier, Director of the Tennessee Manufacturing Extension Partnership. She explained that the Manufacturing Extension Partnership (MEP) is a public-private partnership with centers in all 50 states and Puerto Rico. It is dedicated to providing small and medium-sized manufacturers with the support they need to reduce costs, improve efficiencies, create new products and find new markets. The program is dedicated to bolstering the state of American manufacturing, as the investment in research and development from a manufacturing perspective has decreased significantly. Hagan-Dier further noted that what is frequently happening now in manufacturing is that products are being invented by American manufacturers, but the actual manufacturing is taking place somewhere else. One of the core missions of the MEP is to change this and revert to an “Invent Here, Manufacture Here” model once more.

For more information on the work of ARMI, click here: https://www.armiusa.org/

For more information on the work of Advanced Solutions, click here: https://www.advancedsolutions.com/overview/

For more information on the Manufacturing Extension Partnership, click here: https://www.nist.gov/mep