The course is designed to train and evaluate a bolter's ability to inspect and assemble bolted joints in an effective and safe manner. Participants will understand the principles and practices of safe bolted joint assembly as outlined in Appendix A of ASME PCC-1: Guidelines for Pressure Boundary Bolted Flange Joint Assembly. Appendix A of ASME PCC-1 provides a set of guidelines for pressure boundary bolted flange joint assembly. The general entry level role is the Level 1 Bolting Assembler. This course covers the training concepts identified for the level 1 bolting assembler.

This course is part of ASME’s Bolted Flange Joint Assembly Program, which provides formal on demand training by fostering a deeper understanding of topics and concepts defined in ASME PCC-1 Appendix A.

This course is a prerequisite for the Level 2 Bolting Assembler Qualification Program.

The learner will earn a microcredential for each level by completing courses covering the 4 skills levels:

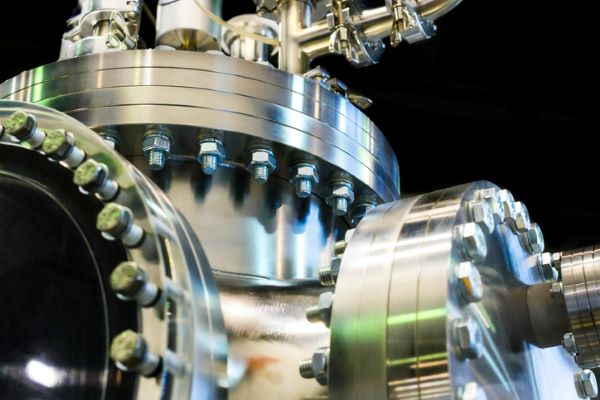

- Level 1: Individual should be able to identify the main components of a bolted flange joint including the bolts, nuts, flanges, gaskets, and lubrication. This individual should also have a basic awareness of bolted flange joints and general terminology of bolting tools and equipment.

- Level 2: Individual should be able to perform general pre-assembly activities of bolted flange joints, such as cleaning and inspection, as well as assembly activities such as gasket and bolt installation, alignment, and manual torque tightening.

- Level 3: Individual should be knowledgeable with in depth concepts of assembly requirements such as proper use of manual tightening equipment methods and pre, in-process, and post assembly quality assurance. This individual should also have an in depth understanding of the reasons why the majority of requirements for bolted flange joint assembly exists.

- Level 4: Individual should have advanced knowledge of all aspects of bolted flange joint assembly and should be able to develop and maintain bolted flange joint assembly procedures, training processes, and provide detailed oversight and guidance to bolted flange joint program.

By participating in this course, you will learn how to successfully:

- Perform the pre-tightening activities applicable to a bolter’s job/function and have a basic awareness of bolted flange joints.

- Identify and differentiate between main components of bolted flange joints as outlined in Appendix A of ASME PCC-1: Pressure Boundary Bolted Flange Joint Assembly, such as the proper identification of flange, bolting, gasket, and lubricants materials by way of gaining a thorough understanding of identification markings and applicable design standards.

- Apply common tooling and terminology to perform proper bolt lubrication, stud installation and proper documentation/tagging.

- Recognize the proper assembly of bolted flange joints.

Who should attend?

Anyone involved in the assembly, disassembly or quality assurance of bolted joints; Major operators and contractors involved in oil and gas, petrochemical and power generation, or any industry that uses bolted flange joint assemblies. Anyone desiring to pursue additional bolting assembler skill levels, such as skill levels 2, 3, or 4.

Course participants are expected to have:

- Access to computer equipment and a reliable internet connection

- A calculator

- Software to display PDF files (such as Adobe Reader)

A Digital Badge and a Certificate of Completion will be issued to registrants who successfully complete the course and achieve a passing score of 75% or higher on the final exam.