5 Questions on How to Power Smart IoT Devices

5 Questions on How to Power Smart IoT Devices

Ron Stull, a power systems engineer at CUI Inc., discusses how engineers can better design smart IoT devices by considering advanced ac/dc power supplies. Photo: Unsplash

With the rise of smart devices and the Internet of Things (IoT), the need for low voltage dc is everywhere. Once relatively “dumb” appliances that ran on ac and mechanical control now have more complex electronic controls and wireless communication integrated into them.

Today, modern smart homes include digital voice assistants, wireless smart bulbs, or smart thermostats. These devices depend on Wi-Fi connectivity, voice commands, and artificial intelligence to learn and assist in your daily routines.

The new smart features are likely controlled by a sophisticated integrated circuit that runs on a low dc voltage. Still, power is distributed via ac power, creating a need to convert from ac to dc. In addition to providing a clean dc power rail to the load, these ac/dc power supplies must also be efficient, reliable, and small.

Finding an off-the-shelf power supply that is optimized for your needs can be challenging. Often you are left with more than you need.

Ron Stull, Power Systems Engineer at CUI Inc., speaks with us on how engineers can correctly select core ac/dc power supply converters that provide them with the freedom and flexibility to optimize their conversion needs.

Q1: What is the first concern when selecting an appropriate ac/dc power supply converter for smart devices?

Ron Stull: Smart devices tend to be small and relatively inexpensive. If you think about the most popular smart devices for your home on the market today, such as the Alexa voice assistant or the Ecobee smart thermostat, they’re often part of a larger network of smart devices throughout the home. If these devices were too large or expensive, consumers would be less inclined to populate their homes with them, and it would defeat the idea of a smart home. For devices like these that will run on low dc voltages, the power supply will significantly impact the device’s overall form factor and cost. However, finding an off-the-shelf power supply with the features you need without those you don’t can be difficult, if not impossible, and you may be left with a larger, more expensive power supply than you need.

You May Also Like: Differences Between Input and Output Plugs for Your Power Adapter

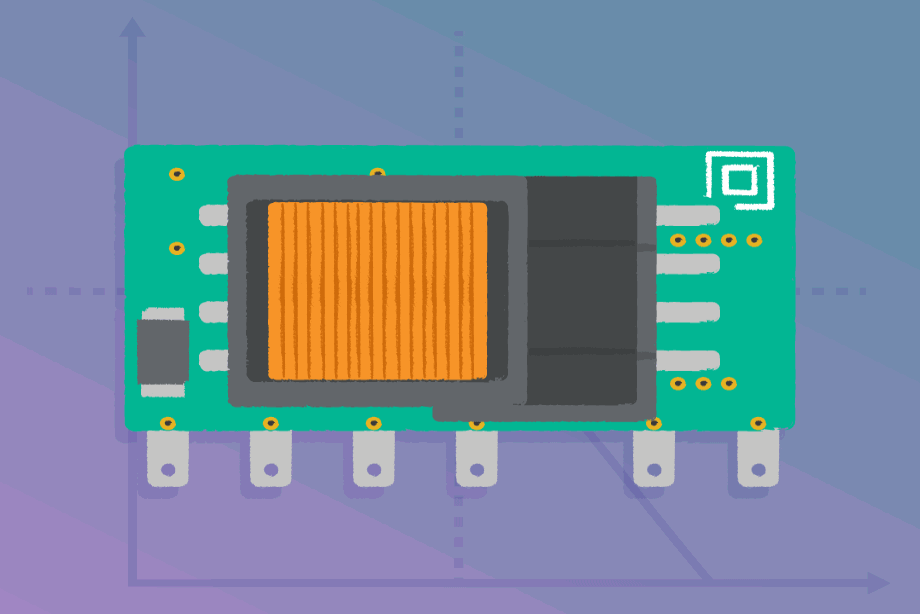

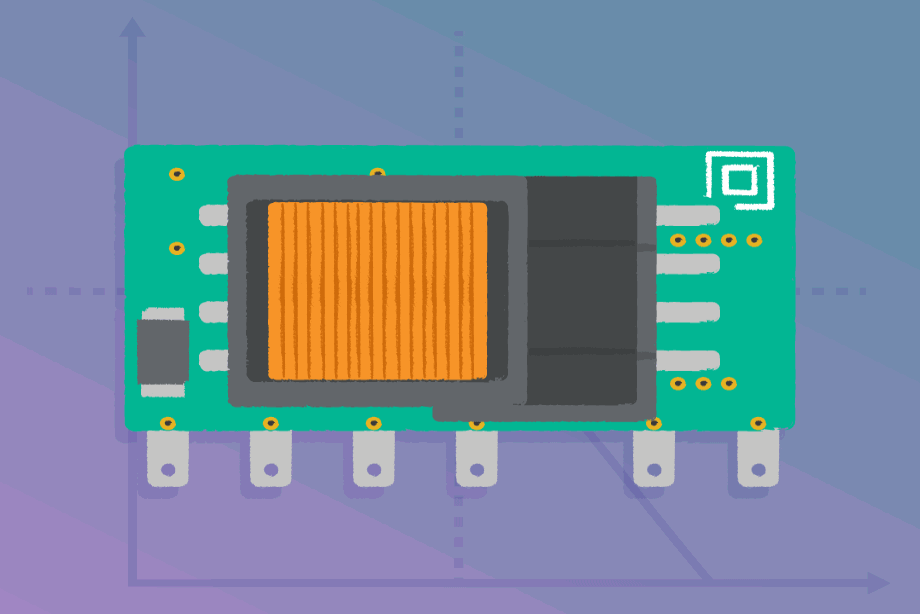

Electromagnetic interference (EMI) filters are one of the main components that take up significant space in a power supply but may not always be needed. Sometimes, instead of using an internal filter, you can think of the design holistically to determine whether inside the power supply is the best location for the EMI filter. Perhaps, the more extensive system is already filtering for EMI further upstream, or the noise between the ac inlet and the power supply is far enough away that an internal filter may prove ineffective. It could also be the case that a particular application requires more or less immunity than is typical. In these cases, it may make the most sense to go with a more flexible power supply like the PBO series from CUI. This ac/dc converter provides a power train that is designed to meet the most common safety standards (61558, 60335, 62368) while leaving the input and output filtering to the user.

Q2: What does an engineer gain by omitting input filtering?

R.S: In some cases, the “smart” technology is being retrofitted to fit into an existing application, and the form factor may be fixed. In other cases, the nature of the device leads to unique shapes and the power supply has to conform to those boundaries. Excluding the EMI filtering from the power supply decreases the power supply’s overall form factor, giving the user much more flexibility in placement and layout. This essentially provides two small blocks to place rather than one large block, making it easier to fit into and better utilize the space available.

Q3: What are other power optimization decisions engineers can make to perfect their design?

R.S: Power supply design is often a balancing act between size, cost, and performance, and the power supply manufacturer’s particular blend of the three likely will not align perfectly with your priorities. Some devices, such as smart security cameras, may emphasize reliability and performance much more than cost or form factor. Using a more flexible ac/dc allows the user to select components based on their design priorities. For instance, the user may want a bulk cap with longer life to increase reliability or perhaps a larger capacitance to increase hold-up time after a power outage. In either case, the user can select the bulk capacitor that is best for their design goals.

Recommended for You: 7 Wearable Devices for 2020

Q4: What are the possible cost savings associated with using an advanced ac/dc power supply?

R.S: The ac/dc power supply provides the user with greater control over the cost of the end solution. Instead of being stuck with the circuits and components chosen by a power supply manufacturer, the user can select or omit components based on their own performance and cost goals. For instance, in applications with less stringent EMI requirements, significant cost savings can be had by leaving out large and expensive filter components such as common mode chokes and inductors. The user would typically be stuck within an ordinary power supply.

Q5: Ultimately, what would drive an engineer to choose an advanced ac/dc power supply core?

R.S: Most engineers do not want to design custom power supplies for their projects due to the cost, development time, and risk involved. However, most off-the-shelf power supplies are not optimized for their application. In cases where space is scarce or special performance requirements exist, using an ac/dc core rather than a complete power supply gives the system designer control over the input and output filtering design as you’d have in a custom power supply. By not requiring them to design the power train allows the engineer to design the power supply around their application rather than their application around the power supply.

Carlos M. González is special projects manager.

Today, modern smart homes include digital voice assistants, wireless smart bulbs, or smart thermostats. These devices depend on Wi-Fi connectivity, voice commands, and artificial intelligence to learn and assist in your daily routines.

The new smart features are likely controlled by a sophisticated integrated circuit that runs on a low dc voltage. Still, power is distributed via ac power, creating a need to convert from ac to dc. In addition to providing a clean dc power rail to the load, these ac/dc power supplies must also be efficient, reliable, and small.

Finding an off-the-shelf power supply that is optimized for your needs can be challenging. Often you are left with more than you need.

Ron Stull, Power Systems Engineer at CUI Inc., speaks with us on how engineers can correctly select core ac/dc power supply converters that provide them with the freedom and flexibility to optimize their conversion needs.

Q1: What is the first concern when selecting an appropriate ac/dc power supply converter for smart devices?

Ron Stull: Smart devices tend to be small and relatively inexpensive. If you think about the most popular smart devices for your home on the market today, such as the Alexa voice assistant or the Ecobee smart thermostat, they’re often part of a larger network of smart devices throughout the home. If these devices were too large or expensive, consumers would be less inclined to populate their homes with them, and it would defeat the idea of a smart home. For devices like these that will run on low dc voltages, the power supply will significantly impact the device’s overall form factor and cost. However, finding an off-the-shelf power supply with the features you need without those you don’t can be difficult, if not impossible, and you may be left with a larger, more expensive power supply than you need.

You May Also Like: Differences Between Input and Output Plugs for Your Power Adapter

Electromagnetic interference (EMI) filters are one of the main components that take up significant space in a power supply but may not always be needed. Sometimes, instead of using an internal filter, you can think of the design holistically to determine whether inside the power supply is the best location for the EMI filter. Perhaps, the more extensive system is already filtering for EMI further upstream, or the noise between the ac inlet and the power supply is far enough away that an internal filter may prove ineffective. It could also be the case that a particular application requires more or less immunity than is typical. In these cases, it may make the most sense to go with a more flexible power supply like the PBO series from CUI. This ac/dc converter provides a power train that is designed to meet the most common safety standards (61558, 60335, 62368) while leaving the input and output filtering to the user.

Q2: What does an engineer gain by omitting input filtering?

R.S: In some cases, the “smart” technology is being retrofitted to fit into an existing application, and the form factor may be fixed. In other cases, the nature of the device leads to unique shapes and the power supply has to conform to those boundaries. Excluding the EMI filtering from the power supply decreases the power supply’s overall form factor, giving the user much more flexibility in placement and layout. This essentially provides two small blocks to place rather than one large block, making it easier to fit into and better utilize the space available.

Q3: What are other power optimization decisions engineers can make to perfect their design?

R.S: Power supply design is often a balancing act between size, cost, and performance, and the power supply manufacturer’s particular blend of the three likely will not align perfectly with your priorities. Some devices, such as smart security cameras, may emphasize reliability and performance much more than cost or form factor. Using a more flexible ac/dc allows the user to select components based on their design priorities. For instance, the user may want a bulk cap with longer life to increase reliability or perhaps a larger capacitance to increase hold-up time after a power outage. In either case, the user can select the bulk capacitor that is best for their design goals.

Recommended for You: 7 Wearable Devices for 2020

Q4: What are the possible cost savings associated with using an advanced ac/dc power supply?

R.S: The ac/dc power supply provides the user with greater control over the cost of the end solution. Instead of being stuck with the circuits and components chosen by a power supply manufacturer, the user can select or omit components based on their own performance and cost goals. For instance, in applications with less stringent EMI requirements, significant cost savings can be had by leaving out large and expensive filter components such as common mode chokes and inductors. The user would typically be stuck within an ordinary power supply.

Q5: Ultimately, what would drive an engineer to choose an advanced ac/dc power supply core?

R.S: Most engineers do not want to design custom power supplies for their projects due to the cost, development time, and risk involved. However, most off-the-shelf power supplies are not optimized for their application. In cases where space is scarce or special performance requirements exist, using an ac/dc core rather than a complete power supply gives the system designer control over the input and output filtering design as you’d have in a custom power supply. By not requiring them to design the power train allows the engineer to design the power supply around their application rather than their application around the power supply.

Carlos M. González is special projects manager.