A 3D-Printed Robot, No Electronics Required

A 3D-Printed Robot, No Electronics Required

Researchers at the University of California, San Diego have developed a walking robot that can be printed in a single step, without electronics or complex assembly.

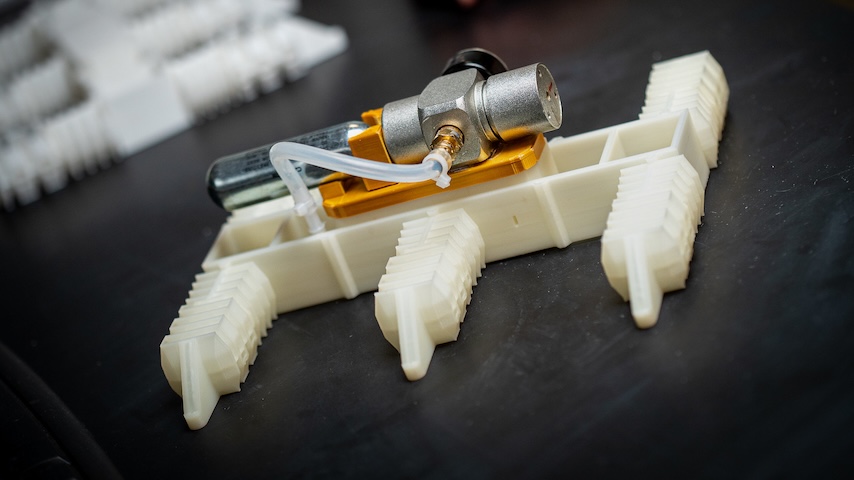

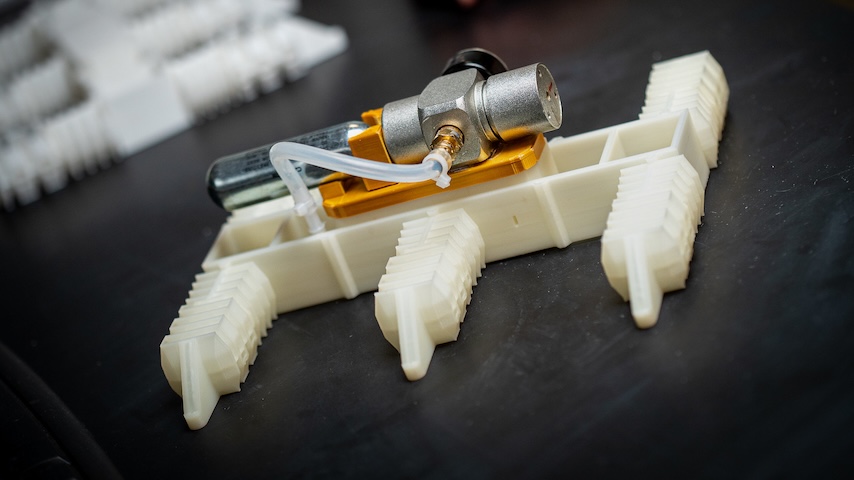

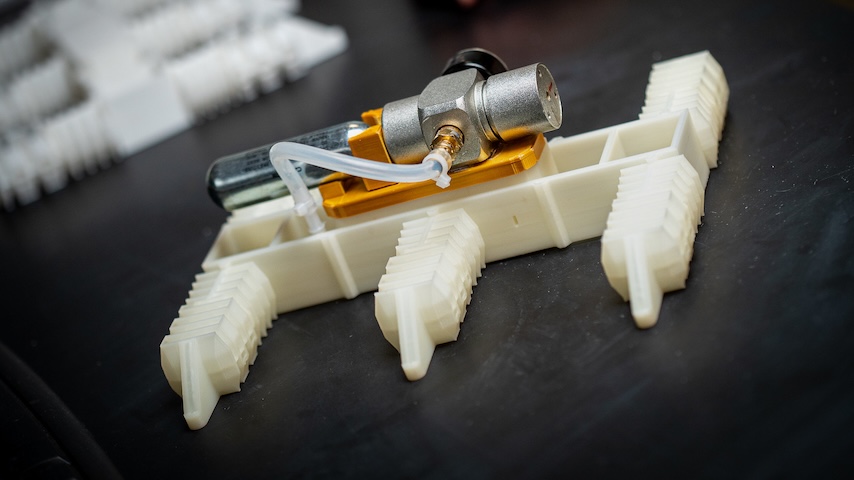

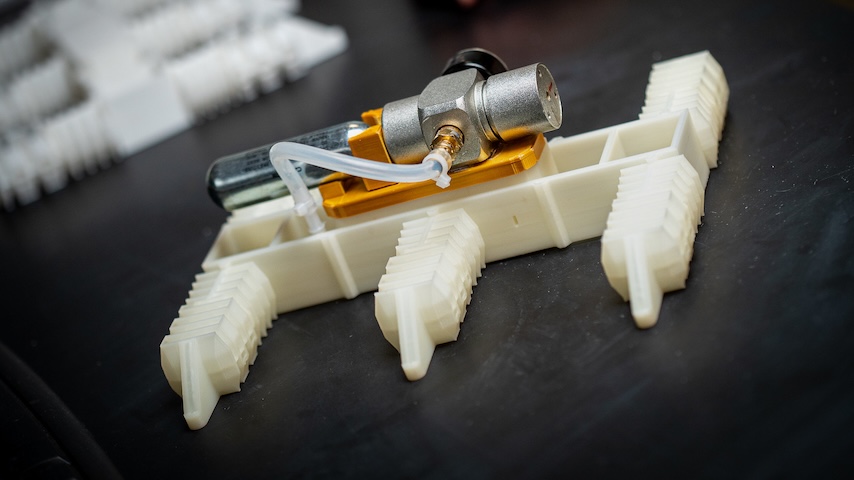

Powered solely by compressed gas, a new walking robot emerges fully formed from a standard desktop 3D printer using an inexpensive, flexible filament. Designed for simplicity and affordability—each unit costs about $20—these soft-bodied machines operate without motors or circuits, making them ideal for environments where traditional electronics would fail.

A research team from the Jacobs School of Engineering's Bioinspired Robotics Laboratory at the University of California, San Diego developed and tested the robot on various surfaces and even underwater. The robot can walk so long as it remains connected to a pressurized air source or a small gas cartridge.

Their findings are detailed in “Monolithic Desktop Digital Fabrication of Autonomous Walking Robots,” recently published in Advanced Intelligent Systems.

“Using desktop 3D printers to fabricate a functional monolithic soft robot has long been a challenging problem in the field of robotics,” explained Michael Tolley, a professor in the UC San Diego Department of Mechanical and Aerospace Engineering and the paper’s senior author. “Since soft robots are often powered by air, a common issue with printed robots has been the presence of defects that lead to air leakage.”

At the project’s outset, the researchers developed a new method to 3D print airtight structures called the Eulerian path method, Tolley continued.

“We set a research goal to create a monolithic walking robot, as this topic is not only challenging but also intriguing," he said. “Based on our newly designed method, we developed and tested the functional components of the robot part by part, refining each one through hundreds of iterations.”

The result was a monolithic robot that can walk straight out of a 3D printer.

Simplicity was the team's top priority throughout the entire research process.

Discover the Benefits of ASME Membership

“We aimed to develop a robot that could be printed in a single process without any manual post-assembly,” he said. “This way, the robot could be shared with the public and replicated by anyone, even without an engineering background.”

Designing and developing this 3D-printed soft robot came with multiple challenges, the most significant of which was designing functional pneumatic components that could be realized using a single 3D-printed soft material.

“For example, the key component of the robot is an oscillating valve, which functions as the robot’s brain. It receives a constant pressure input and cyclically outputs pressures to four different phases, powering the stepping motion of the legs," Tolley said. “We had to design rigid structural parts, air valves, tubes, hinges, and mechanical linkages—all using the same soft material.”

The team did all this design work manually. To achieve a stable and functional oscillating valve, they created more than 180 different designs through iterations, with each version taking about 16 hours to 3D print, he added.

“After so much testing, we are confident in saying that the final design was a success,” said Tolley, adding that once it has been further developed and refined, the robot couldb e put to good use in multiple applications.

The 3D CAD designs of the robot, including its brain—the oscillating valve—are all open source as well. Tolley noted that all these files are included in the supplementary materials section of their paper, “Monolithic Desktop Digital Fabrication of Autonomous Walking Robots.”

“Currently, the robot may be of interest to educators, researchers, and DIY makers,” Tolley continued. “It can serve as an educational tool to inspire the younger generation to explore science and engineering. For real-world applications, the low-cost and simple fabrication approach provides major advantages. The robot can be used for scientific exploration to collect data or deploy equipment in remote or inaccessible environments, or in disaster response to search for survivors.”

Since the robot is powered by air and contains no electronic components, it would also be suitable for environments with high magnetic fields, spark risks, or even underwater, he added.

Jim Romeo is a technology writer in Chesapeake, Va.

A research team from the Jacobs School of Engineering's Bioinspired Robotics Laboratory at the University of California, San Diego developed and tested the robot on various surfaces and even underwater. The robot can walk so long as it remains connected to a pressurized air source or a small gas cartridge.

Their findings are detailed in “Monolithic Desktop Digital Fabrication of Autonomous Walking Robots,” recently published in Advanced Intelligent Systems.

“Using desktop 3D printers to fabricate a functional monolithic soft robot has long been a challenging problem in the field of robotics,” explained Michael Tolley, a professor in the UC San Diego Department of Mechanical and Aerospace Engineering and the paper’s senior author. “Since soft robots are often powered by air, a common issue with printed robots has been the presence of defects that lead to air leakage.”

At the project’s outset, the researchers developed a new method to 3D print airtight structures called the Eulerian path method, Tolley continued.

“We set a research goal to create a monolithic walking robot, as this topic is not only challenging but also intriguing," he said. “Based on our newly designed method, we developed and tested the functional components of the robot part by part, refining each one through hundreds of iterations.”

The result was a monolithic robot that can walk straight out of a 3D printer.

Simplicity was the team's top priority throughout the entire research process.

Discover the Benefits of ASME Membership

“We aimed to develop a robot that could be printed in a single process without any manual post-assembly,” he said. “This way, the robot could be shared with the public and replicated by anyone, even without an engineering background.”

Designing and developing this 3D-printed soft robot came with multiple challenges, the most significant of which was designing functional pneumatic components that could be realized using a single 3D-printed soft material.

“For example, the key component of the robot is an oscillating valve, which functions as the robot’s brain. It receives a constant pressure input and cyclically outputs pressures to four different phases, powering the stepping motion of the legs," Tolley said. “We had to design rigid structural parts, air valves, tubes, hinges, and mechanical linkages—all using the same soft material.”

The team did all this design work manually. To achieve a stable and functional oscillating valve, they created more than 180 different designs through iterations, with each version taking about 16 hours to 3D print, he added.

“After so much testing, we are confident in saying that the final design was a success,” said Tolley, adding that once it has been further developed and refined, the robot couldb e put to good use in multiple applications.

The 3D CAD designs of the robot, including its brain—the oscillating valve—are all open source as well. Tolley noted that all these files are included in the supplementary materials section of their paper, “Monolithic Desktop Digital Fabrication of Autonomous Walking Robots.”

“Currently, the robot may be of interest to educators, researchers, and DIY makers,” Tolley continued. “It can serve as an educational tool to inspire the younger generation to explore science and engineering. For real-world applications, the low-cost and simple fabrication approach provides major advantages. The robot can be used for scientific exploration to collect data or deploy equipment in remote or inaccessible environments, or in disaster response to search for survivors.”

Since the robot is powered by air and contains no electronic components, it would also be suitable for environments with high magnetic fields, spark risks, or even underwater, he added.

Jim Romeo is a technology writer in Chesapeake, Va.