Da Vinci’s Aerial Screw Finds New Life as a Low-Noise Drone Propeller

Da Vinci’s Aerial Screw Finds New Life as a Low-Noise Drone Propeller

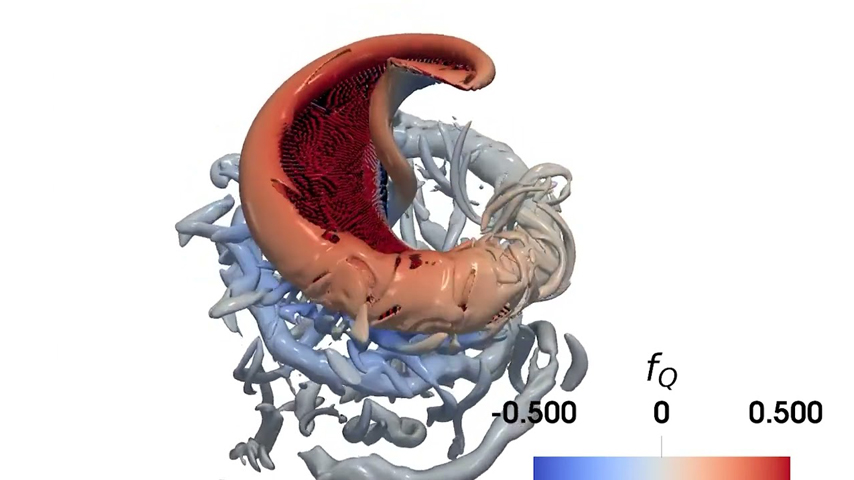

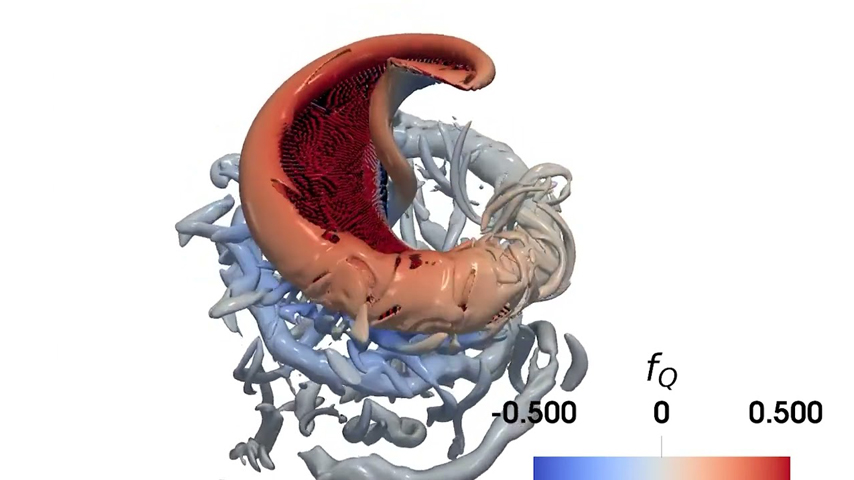

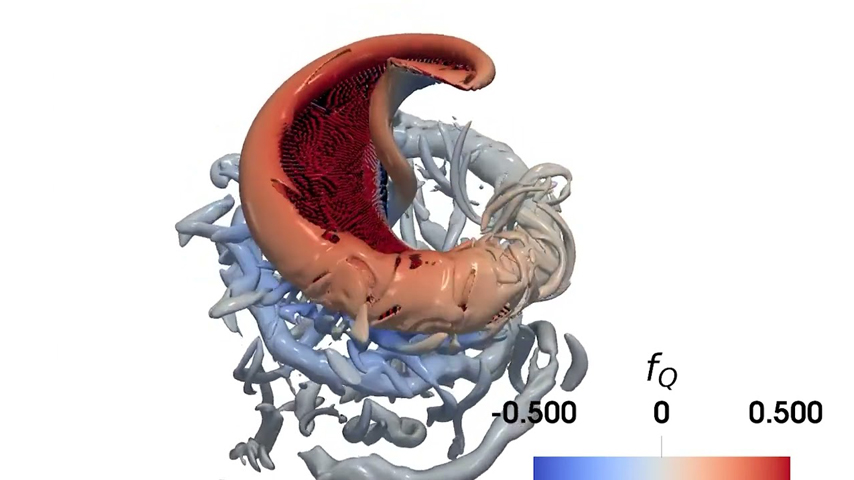

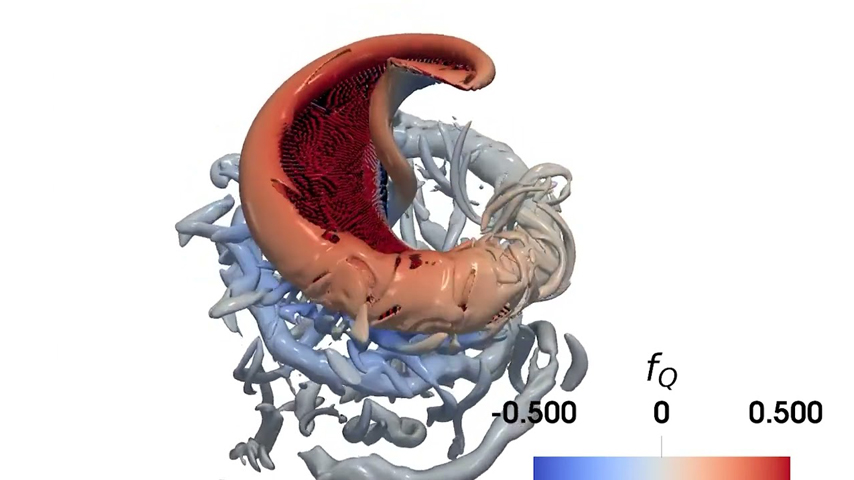

The boundary of vortices around a helical screw-type propeller.

The following is an excerpt from the January 2025 Mechanical Engineering article, “Buzz Killer.” The fully digital issue is available to ASME members at magazine.asme.org.

For homeowners, picnickers, and privacy enthusiasts, the buzz of a drone is an annoyance. For the military, that sound is worse—it’s a dead giveaway. “Even a small drone makes a lot of noise,” said Rajat Mittal, a professor of mechanical engineering at Johns Hopkins University in Baltimore. “Once you start thinking about delivering a 10-pound Amazon delivery or something, you can imagine the kind of noise that these drones are going to make.”

With a grant from the Army Research Office, Mittal and a Johns Hopkins team that included Jung-Hee Seo, an associate research professor of mechanical engineering, and Suryansh Prakhar, a mechanical engineering doctoral student, set out to mitigate the whine of these quadcopters.

They first turned to airborne products of evolution for inspiration. Flying insects of roughly the same size can make wildly different amounts of noise. The mosquito, for instance, is famous for its annoying buzz, to the point of having children’s books written about it.

“But from a same-size fruit fly, you will not be able to hear the noise from their wings,” Mittal said. “The wings of fruit flies have a much larger area than the wings of, for instance, mosquitoes, and because they have larger area wings, they actually flap them at a lower frequency.”

ME is Fully Digital

Mittal and his team conjectured that if they could increase the area of a drone’s rotor, they would generate more lift per revolution per minute (RPM), allowing for a reduction in RPM and ultimately slashing noise as well. So, for the purposes of noise reduction, they assumed that the larger the rotor, the better.

This insight led them to the design of a Renaissance artist and polymath.

Sometime in the 1480s, Leonardo da Vinci sketched out a concept for a flying contraption in his notebooks. His “aerial screw” looks like one-and-a-half turns of a corkscrew—essentially an uninterrupted spiral rotor.

“It dawned on us that this is the ultimate large area rotor that one can think of—the area is continuous, it’s not individual blades,” Mittal said. “If our hypothesis is correct, then the da Vinci rotor should produce less noise.”

To prove it, the researchers decided to make a 3D model of the screw and run it through a few virtual paces. Thankfully, that didn’t require extrapolating from the tiny centuries-old sketch drawn by the painter/scientist/engineer/architect. Researchers at the University of Maryland had already created a da Vinci aerial-screw-powered drone two years before, so the Johns Hopkins team used its design to create its own for simulation.

Running the simulations was data heavy business. “Each of these simulations runs on about 256 parallel processors—and they run for many days,” Mittal said. “If I were to just kind of back extrapolate Moore’s law to 15 years ago, it would probably take many months to run a single simulation.”

Continue reading in the January 2025 Mechanical Engineering article, “Buzz Killer.”

Michael Abrams is a technology writer in Westfield, N.J.