Leveraging Symbiosis for Self-Healing Concrete

Leveraging Symbiosis for Self-Healing Concrete

Researchers at Texas A&M University have developed a synthetic lichen system to help concrete self-repair cracks.

It’s said that half of all the buildings in the entire world are constructed, at least partially, from concrete. While it is hard to quantify exactly how much global infrastructure relies on this popular building material, there’s no question that builders gravitate toward it because of its winning combination of strength and low cost. This age-old mixture of crushed stone, sand, and powdered clay, hardens when hydrated with water. The resulting material is strong enough to support everything from a city skyscraper to a highway overpass.

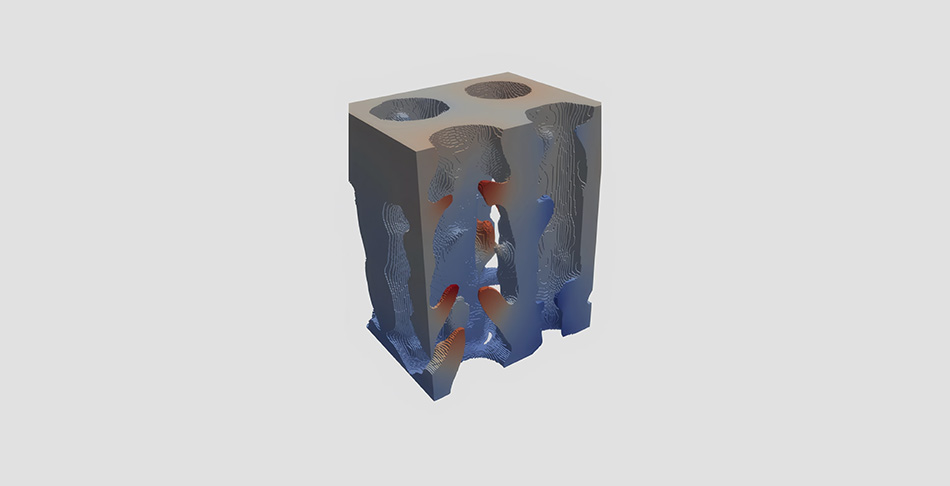

There’s only one problem: concrete can, and does, suffer cracks over time. Those cracks, both large and small, can ultimately contribute to structural failure, putting both property and lives at risk. The United States spends an estimated tens of billions of dollars each year to both detect dangerous cracks and then remediate them through the application of trusted patching compounds.

To address concrete cracking, many engineers have looked at developing new and innovative methods that allow concrete to repair its own imperfections. Many of these promising techniques harness microbes to metabolize organic compounds to fill in the gaps caused by freeze-thaw cycles, drying shrinkage, and/or heavy loads.

“Self-healing concrete has been studied for several decades,” said Congrui Grace Jin, Ph.D., assistant professor in the department of engineering, technology, and industrial distribution at Texas A&M University. “But many of these self-healing concretes use bacteria to generate calcium carbonate, which can heal the cracks. But the problem is that these techniques rely on a single strain or species of bacteria to work. And if you want to keep those bacteria alive so they can continue to heal the concrete, you have to provide the right nutrients.”

Without those nutrients, these so-called self-healing concrete applications aren’t autonomous. To ensure that the bacteria survive—and continue providing its natural repairing fill—inspectors or other construction workers must generate feeder material and then inject or spray those nutrients into cracks. Employing people to both find the cracks that need repair and apply the feeder material simply isn’t practical or cost effective. Jin knew there had to be a better way. She and her colleagues found it by looking at lichen systems, or complex communities of fungi and microbes that work together in a symbiotic manner.

Discover the Benefits of ASME Membership

“In nature, bacteria or fungi don’t exist as single individuals. They always collaborate with other species,” she said. “I think nature has the best design—and we are inspired by the interaction and cooperation between different species. We decided to create a synthetic community.”

This synthetic system leverages cyanobacteria, a species of bacteria that relies on photosynthesis to provide its own food, coupled with filamentous fungi, which produce the material that can fill cracks through biomineralization. As a result, the system only needs air, light, and water to promote self-healing in concrete structures.

“Basically, the cyanobacteria convert the carbon dioxide in the air into organic nutrients for the fungi,” Jin explained. “The fungi then attract that matter into their body and generate calcium carbonate. The calcium carbonate can heal the crack in the concrete. This system can be autonomous because the cyanobacteria and fungi work together—and you don’t need a human being to provide anything.”

When Jin and colleagues at the University of Nebraska-Lincoln, including Richard Wilson, Nisha Rokaya, and Erin Carr, tested the material in the laboratory, they saw that it produced ample calcium carbonate to fill different cracks—except in areas where there is no sunlight.

“Because the cyanobacteria rely on sunlight, we cannot heal cracks deep, deep inside the concrete,” she said.

With positive results in the laboratory, Jin and her team are now testing the system in real-world conditions to ensure it still works amidst temperature fluctuations and naturally occurring concentrations of carbon dioxide in the air.

“In the lab, we have a very high concentration of carbon dioxide and nitrogen to make the system very comfortable,” she said. “But we will test everything in realistic conditions to make sure it works as it should.”

Beyond the creation of this synthetic lichen system, Jin is also thinking about community perception of such biological healing methods. Other concrete self-repair methods, including those she’s developed, sometimes require genetic editing which can be a hard sell for many people who don’t understand the science. She is currently collaborating with social scientists at Texas A&M to understand what the public thinks about using living organisms in construction and what it might take to promote greater acceptance and adoption.

“Many people are worried about putting living microorganisms into the built environment,” she said. “But we don’t know if those worries are based on some scientific reason or if it’s just due to human perception about the organisms behaving unexpectedly or posing health risks. This is an important thing to understand before we start using these techniques.”

Kayt Sukel is a technology writer and author in Houston.

There’s only one problem: concrete can, and does, suffer cracks over time. Those cracks, both large and small, can ultimately contribute to structural failure, putting both property and lives at risk. The United States spends an estimated tens of billions of dollars each year to both detect dangerous cracks and then remediate them through the application of trusted patching compounds.

To address concrete cracking, many engineers have looked at developing new and innovative methods that allow concrete to repair its own imperfections. Many of these promising techniques harness microbes to metabolize organic compounds to fill in the gaps caused by freeze-thaw cycles, drying shrinkage, and/or heavy loads.

“Self-healing concrete has been studied for several decades,” said Congrui Grace Jin, Ph.D., assistant professor in the department of engineering, technology, and industrial distribution at Texas A&M University. “But many of these self-healing concretes use bacteria to generate calcium carbonate, which can heal the cracks. But the problem is that these techniques rely on a single strain or species of bacteria to work. And if you want to keep those bacteria alive so they can continue to heal the concrete, you have to provide the right nutrients.”

Without those nutrients, these so-called self-healing concrete applications aren’t autonomous. To ensure that the bacteria survive—and continue providing its natural repairing fill—inspectors or other construction workers must generate feeder material and then inject or spray those nutrients into cracks. Employing people to both find the cracks that need repair and apply the feeder material simply isn’t practical or cost effective. Jin knew there had to be a better way. She and her colleagues found it by looking at lichen systems, or complex communities of fungi and microbes that work together in a symbiotic manner.

Discover the Benefits of ASME Membership

“In nature, bacteria or fungi don’t exist as single individuals. They always collaborate with other species,” she said. “I think nature has the best design—and we are inspired by the interaction and cooperation between different species. We decided to create a synthetic community.”

This synthetic system leverages cyanobacteria, a species of bacteria that relies on photosynthesis to provide its own food, coupled with filamentous fungi, which produce the material that can fill cracks through biomineralization. As a result, the system only needs air, light, and water to promote self-healing in concrete structures.

“Basically, the cyanobacteria convert the carbon dioxide in the air into organic nutrients for the fungi,” Jin explained. “The fungi then attract that matter into their body and generate calcium carbonate. The calcium carbonate can heal the crack in the concrete. This system can be autonomous because the cyanobacteria and fungi work together—and you don’t need a human being to provide anything.”

When Jin and colleagues at the University of Nebraska-Lincoln, including Richard Wilson, Nisha Rokaya, and Erin Carr, tested the material in the laboratory, they saw that it produced ample calcium carbonate to fill different cracks—except in areas where there is no sunlight.

“Because the cyanobacteria rely on sunlight, we cannot heal cracks deep, deep inside the concrete,” she said.

With positive results in the laboratory, Jin and her team are now testing the system in real-world conditions to ensure it still works amidst temperature fluctuations and naturally occurring concentrations of carbon dioxide in the air.

“In the lab, we have a very high concentration of carbon dioxide and nitrogen to make the system very comfortable,” she said. “But we will test everything in realistic conditions to make sure it works as it should.”

Beyond the creation of this synthetic lichen system, Jin is also thinking about community perception of such biological healing methods. Other concrete self-repair methods, including those she’s developed, sometimes require genetic editing which can be a hard sell for many people who don’t understand the science. She is currently collaborating with social scientists at Texas A&M to understand what the public thinks about using living organisms in construction and what it might take to promote greater acceptance and adoption.

“Many people are worried about putting living microorganisms into the built environment,” she said. “But we don’t know if those worries are based on some scientific reason or if it’s just due to human perception about the organisms behaving unexpectedly or posing health risks. This is an important thing to understand before we start using these techniques.”

Kayt Sukel is a technology writer and author in Houston.