Graphene-based Biosensor Offers Instant Diagnosis

Graphene-based Biosensor Offers Instant Diagnosis

A remote health and environmental monitoring system will deliver instant results when detecting viruses, bacterias, and cancers.

Rapid and polymerase chain reaction (PCR) tests for viruses such as COVID-19 are widely available, but results take anywhere from minutes to days, depending on the type of test. But Soaram Kim, assistant professor in the Department of Electrical and Computer Engineering and the Center for Remote Health Technologies and Systems at Texas A&M University, has developed a biosensor that can provide the same results within seconds. And soon, it won't just be for various pathogens—work is also underway to provide instant detection of other diseases and various cancers, all with a small sample of saliva or blood.

The graphene-based sensor at the heart of a remote health and environmental monitoring system also embraces the Internet of Things (IoT) for fast cloud sharing. In addition to rapid results, the device is portable. Such devices make health care more personalized; Add a decentralized form of healthcare delivery and that leads to efficient, high quality, and early detection of a wide range of diseases, Kim said.

“Long wait times at emergency rooms are really inconvenient, can be deconditioning, and sometimes can be life threatening,” he said. “That's why I'm working on this research so that we can transmit all the data to a doctor or your primary doctor by cell phone or laptop. All the data you collect with my sensor will automatically save on your smartphone or your data cloud. That's my goal.”

An initial prototype designed to detect COVID-19 features a sensor sample holder attached to a large phone-sized device with a touch screen. Power issues with this device led the team to develop another version, one that would attach to a cell phone via USB-C and run on an app. This brought the operational time from just 4 to 6 hours on the initial prototype to at least 12 to 14 hours with the cell phone attachment. But the main goal of the smart phone attachable sensor is to make the system more efficient and convenient for the end-user, Kim said.

Similar Reading: Simple, Sophisticated Sensing Systems Collect Critical Information

When activated, the screen shows a line graph with a steady reading at less than 1 percent when a control sample is added. But when a pathogen-positive saliva or nasal swab sample is added to the sensor, the line graph skyrockets in just moments to illustrate a positive result. When the test is complete, a summary screen appears, complete with a sad smiley face to go along with virus’ detection.

The sensor can be used multiple times as well after a cleanse with hot water or a saline solution. Another addition is a breathalyzer-type attachment that can also carry breath aerosol directly to the sensor.

“So you can just drop your saliva or blow into the sensor, then it will detect the coronavirus,” Kim added. “Currently, I'm trying to detect lung cancer, also mycobacterium tuberculosis, pancreatic cancer, breast cancer, cervical cancer, and other different cancers."

This IoT-based remote health/environmental monitoring system is comprised of physical, chemical, biological, and infrared sensors with machine learning/artificial intelligence. “To prepare the IoT-based remote health/environmental monitoring systems, I'm using graphene, polymer, TMD or transition metal dichalcogenides, TMO or traditional metal oxide, and II-IV and III-V semi-conductor compound materials. Then transferring these materials to substrate, flexible or preparing by 3D printing technique, and then adding an IoT system or smart motoring system,” he explained.

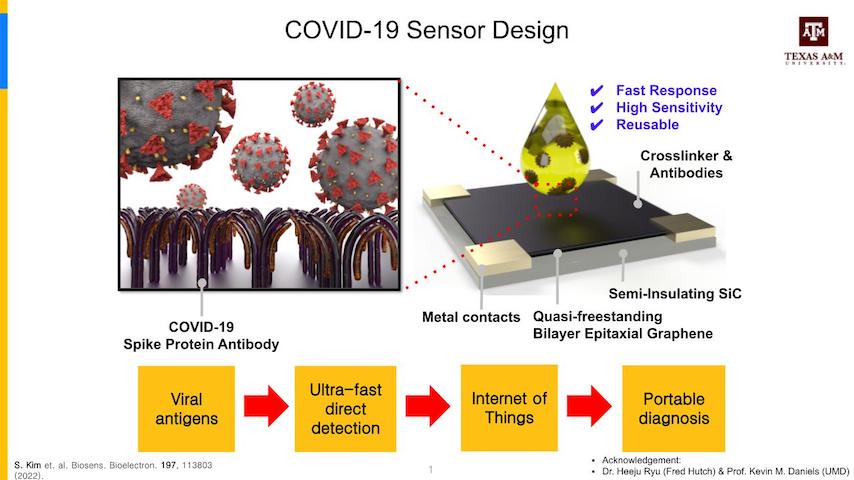

The sensor structure is made from a quasi-freestanding bilayer of epitaxial graphene on silicon carbide. Graphene’s high electrical conductivity, high room temperature mobility, and high surface area make it extremely sensitive to the environment, Kim explained. But it also has poor selectivity, which means something had to be added to graphene to create a heterostructure, he added.

“Graphene allows for a heterostructure without any lattice matching. So normally, when you prepare a structure, you have to think about the lattice matching. If materials' lattice constant don’t match, it will have a lot of strain or defects and it won’t be good for sensing,” he said. “I’m using CVD [chemical vapor deposition] graphene and epitaxial graphene because they are high quality, have good uniformity, and they can be controlled in a monolayer and bilayer.”

Become a Member: How to Join ASME

The researchers are using sublimation silicon from 6H silicon carbide, so when the material is heated, the silicon is removed and the graphene remains. This is followed by another process called hydrogen intercalation, which exposes the epitaxial graphene to hydrogen at 1,000 °C, which gives the graphene uniformity to become quasi-freestanding.

“Quasi-freestanding bilayer epitaxial graphene is an ideal substrate to have heterostructure with other materials for sensing applications,” Kim said.

The COVID sensor features silicone carbide, epitaxial graphene, as well as crosslinkers, antibodies, and biomarkers. The biomarkers enable detection of specific antibody antigen reactions.

"When the reaction happens, this graphene can immediately catch the viral antigens with ultra-fast direct detection, and then we can use the cell phone for our portable diagnosis,” Kim said.

In addition to the Center for Remote Health Technologies and Systems and the Department of Electrical and Computer Engineering at Texas A&M, collaborators include researchers at the University of Maryland College Park, University of Delaware, the Fred Hutchinson Cancer Research Center and the Naval Research Laboratory

Kim has been working on this device throughout his academic career, going back to 2010. While working on the project as a postdoc, his work focused on the chemical/biological and wearable sensors.

Kim is lead author on “Real-time ultra-sensitive detection of SARS-CoV-2 by quasi-freestanding epitaxial graphene-based biosensor,” published in February 2022, which details the sensor’s ability to detect the virus.

But COVID-19 is just one of the many pathogens that can be detected with Kim’s system. He’s working on expanding its capabilities to identify a wide range of viruses, bacterias, and cancers. And by adding machine learning algorithms, the system boasts increased speed and reliability.

You Might Also Enjoy: Hydration Sensors Key to Smart Diapers

It’s also highly sensitive. Compared to current testing methods that require 0.01 to 0.1 nanograms per milliliter of a sample, Kim’s new method requires only one attogram per milliliter—or one billionth of a nanogram.

“I’m trying to detect all different cancers, so using just one droplet of blood or saliva, you can detect all different cancers, diseases, or even gene information. That would be great, because it’s noninvasive,” he said. “Currently, equipment is really expensive—at least $1 million—and to get back results, it takes a few days. PCR takes at least three hours because of the RNA preparation step. In our case, it only takes a few hundred dollars and a few seconds to get results.”

Looking ahead, Kim hopes that the cost-effective nature and rapid response time of his system will benefit healthcare providers who handle in-office testing. But he also would also like to see the biosensor available at drugstores so anyone can get a rapid diagnosis and ultimately faster treatment.

Louise Poirier is senior editor.

The graphene-based sensor at the heart of a remote health and environmental monitoring system also embraces the Internet of Things (IoT) for fast cloud sharing. In addition to rapid results, the device is portable. Such devices make health care more personalized; Add a decentralized form of healthcare delivery and that leads to efficient, high quality, and early detection of a wide range of diseases, Kim said.

“Long wait times at emergency rooms are really inconvenient, can be deconditioning, and sometimes can be life threatening,” he said. “That's why I'm working on this research so that we can transmit all the data to a doctor or your primary doctor by cell phone or laptop. All the data you collect with my sensor will automatically save on your smartphone or your data cloud. That's my goal.”

An initial prototype designed to detect COVID-19 features a sensor sample holder attached to a large phone-sized device with a touch screen. Power issues with this device led the team to develop another version, one that would attach to a cell phone via USB-C and run on an app. This brought the operational time from just 4 to 6 hours on the initial prototype to at least 12 to 14 hours with the cell phone attachment. But the main goal of the smart phone attachable sensor is to make the system more efficient and convenient for the end-user, Kim said.

Similar Reading: Simple, Sophisticated Sensing Systems Collect Critical Information

When activated, the screen shows a line graph with a steady reading at less than 1 percent when a control sample is added. But when a pathogen-positive saliva or nasal swab sample is added to the sensor, the line graph skyrockets in just moments to illustrate a positive result. When the test is complete, a summary screen appears, complete with a sad smiley face to go along with virus’ detection.

The sensor can be used multiple times as well after a cleanse with hot water or a saline solution. Another addition is a breathalyzer-type attachment that can also carry breath aerosol directly to the sensor.

“So you can just drop your saliva or blow into the sensor, then it will detect the coronavirus,” Kim added. “Currently, I'm trying to detect lung cancer, also mycobacterium tuberculosis, pancreatic cancer, breast cancer, cervical cancer, and other different cancers."

Highly sensitive

This IoT-based remote health/environmental monitoring system is comprised of physical, chemical, biological, and infrared sensors with machine learning/artificial intelligence. “To prepare the IoT-based remote health/environmental monitoring systems, I'm using graphene, polymer, TMD or transition metal dichalcogenides, TMO or traditional metal oxide, and II-IV and III-V semi-conductor compound materials. Then transferring these materials to substrate, flexible or preparing by 3D printing technique, and then adding an IoT system or smart motoring system,” he explained.

The sensor structure is made from a quasi-freestanding bilayer of epitaxial graphene on silicon carbide. Graphene’s high electrical conductivity, high room temperature mobility, and high surface area make it extremely sensitive to the environment, Kim explained. But it also has poor selectivity, which means something had to be added to graphene to create a heterostructure, he added.

“Graphene allows for a heterostructure without any lattice matching. So normally, when you prepare a structure, you have to think about the lattice matching. If materials' lattice constant don’t match, it will have a lot of strain or defects and it won’t be good for sensing,” he said. “I’m using CVD [chemical vapor deposition] graphene and epitaxial graphene because they are high quality, have good uniformity, and they can be controlled in a monolayer and bilayer.”

Become a Member: How to Join ASME

The researchers are using sublimation silicon from 6H silicon carbide, so when the material is heated, the silicon is removed and the graphene remains. This is followed by another process called hydrogen intercalation, which exposes the epitaxial graphene to hydrogen at 1,000 °C, which gives the graphene uniformity to become quasi-freestanding.

“Quasi-freestanding bilayer epitaxial graphene is an ideal substrate to have heterostructure with other materials for sensing applications,” Kim said.

The COVID sensor features silicone carbide, epitaxial graphene, as well as crosslinkers, antibodies, and biomarkers. The biomarkers enable detection of specific antibody antigen reactions.

"When the reaction happens, this graphene can immediately catch the viral antigens with ultra-fast direct detection, and then we can use the cell phone for our portable diagnosis,” Kim said.

In addition to the Center for Remote Health Technologies and Systems and the Department of Electrical and Computer Engineering at Texas A&M, collaborators include researchers at the University of Maryland College Park, University of Delaware, the Fred Hutchinson Cancer Research Center and the Naval Research Laboratory

Beyond viruses

Kim has been working on this device throughout his academic career, going back to 2010. While working on the project as a postdoc, his work focused on the chemical/biological and wearable sensors.

Kim is lead author on “Real-time ultra-sensitive detection of SARS-CoV-2 by quasi-freestanding epitaxial graphene-based biosensor,” published in February 2022, which details the sensor’s ability to detect the virus.

But COVID-19 is just one of the many pathogens that can be detected with Kim’s system. He’s working on expanding its capabilities to identify a wide range of viruses, bacterias, and cancers. And by adding machine learning algorithms, the system boasts increased speed and reliability.

You Might Also Enjoy: Hydration Sensors Key to Smart Diapers

It’s also highly sensitive. Compared to current testing methods that require 0.01 to 0.1 nanograms per milliliter of a sample, Kim’s new method requires only one attogram per milliliter—or one billionth of a nanogram.

“I’m trying to detect all different cancers, so using just one droplet of blood or saliva, you can detect all different cancers, diseases, or even gene information. That would be great, because it’s noninvasive,” he said. “Currently, equipment is really expensive—at least $1 million—and to get back results, it takes a few days. PCR takes at least three hours because of the RNA preparation step. In our case, it only takes a few hundred dollars and a few seconds to get results.”

Looking ahead, Kim hopes that the cost-effective nature and rapid response time of his system will benefit healthcare providers who handle in-office testing. But he also would also like to see the biosensor available at drugstores so anyone can get a rapid diagnosis and ultimately faster treatment.

Louise Poirier is senior editor.

Pulse of the Profession: Digital Transformation

To bolster organizational resilience and efficiency—and leverage technologies for competitive advantage—organizations across the engineering landscape are investing in digital transformation.

-pptx.jpg?width=854&height=480&ext=.jpg)