Ultra-Strong Aluminum Alloys Now Possible for AM

Ultra-Strong Aluminum Alloys Now Possible for AM

Purdue University engineers have developed a process that adds transition metals to aluminum at the nanoscale and created ultra-strong alloys without cracking, a first in the industry.

Lightweight, high-strength aluminum alloys are commonly used in manufacturing, especially in the aerospace and automotive industries. However, most commercially available high-strength aluminum alloys cannot be used in additive manufacturing (AM) because they are highly susceptible to hot cracking, which creates defects that can result in deterioration of the aluminum alloy and structural failure of the part. Another drawback with high-strength aluminum alloys is that they do not have large plastic deformability—another requirement for successful AM production.

There is new hope, however, for creating even stronger aluminum alloys that do not crack and are commercially viable. Materials engineers at Purdue University have created a process for making ultra-strong aluminum alloys that are suitable for AM. These alloys show ultra-high strength (exceeding 900 megapascals) which is much higher than most AM Al alloys, as well as plastic deformability.

The research team—Haiyan Wang and Xinghang Zhang, both professors of materials engineering at Purdue University and Anyu Shang, a materials engineering graduate—has pursued high-strength printable Al alloys for four years.

Additively manufactured, high-strength Al alloys generally suffer from hot tearing and cracking. “Our goal,” Zhang said, “has been to develop printable crack-free,-yet-strong, Al alloys. Transition metal elements, such as Fe, Co, and Ni have been largely avoided in traditional manufacturing of Al alloys because they can form large, brittle intermetallic particles in Al alloys, making them brittle. However, we had also speculated that in AM Al alloys, transition-metal intermetallics could have small nanoscale dimensions that would mitigate cracking issues. Using non-popular transition metal elements for AM Al alloys was definitely a counter-intuitive idea to follow.”

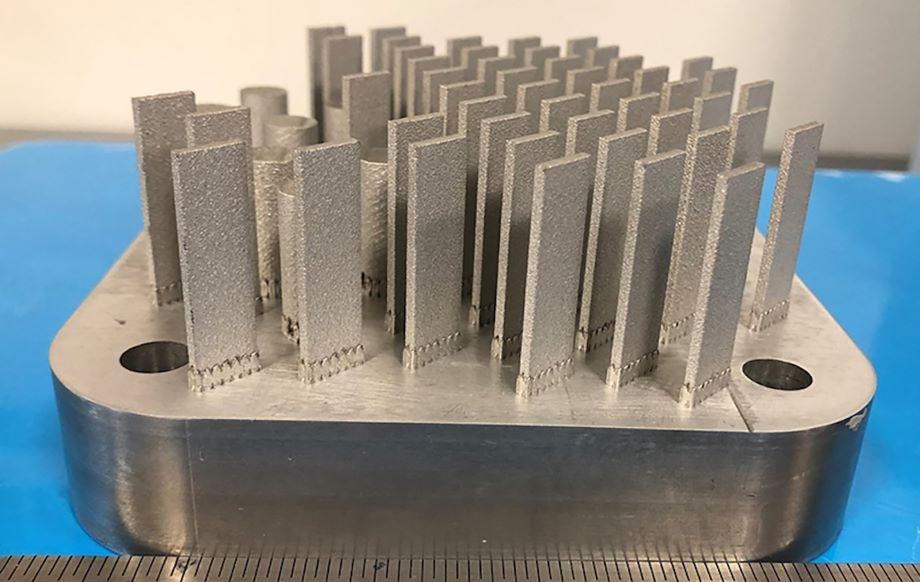

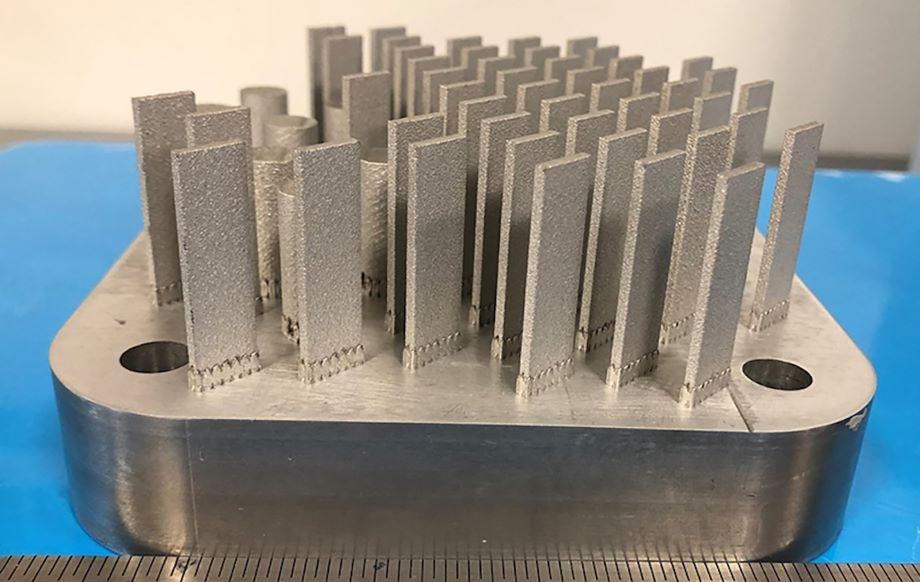

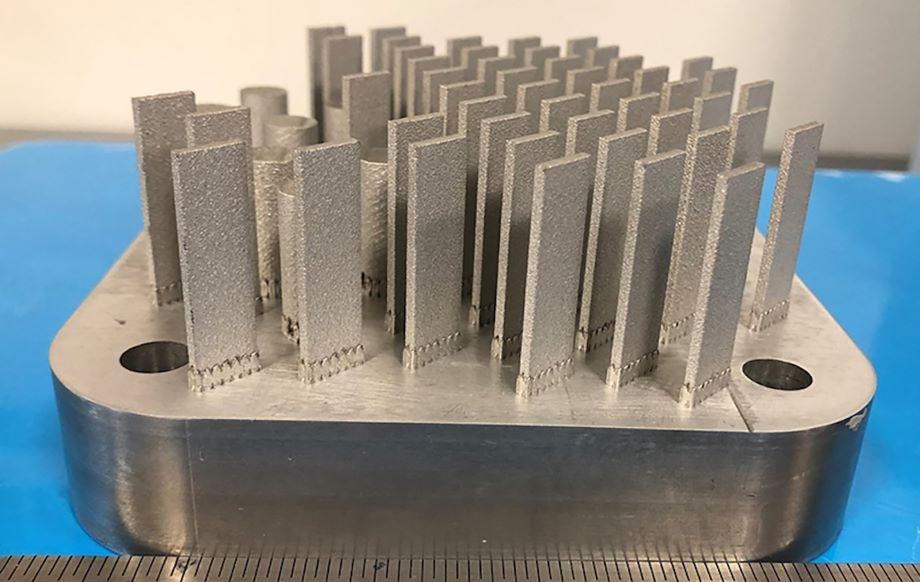

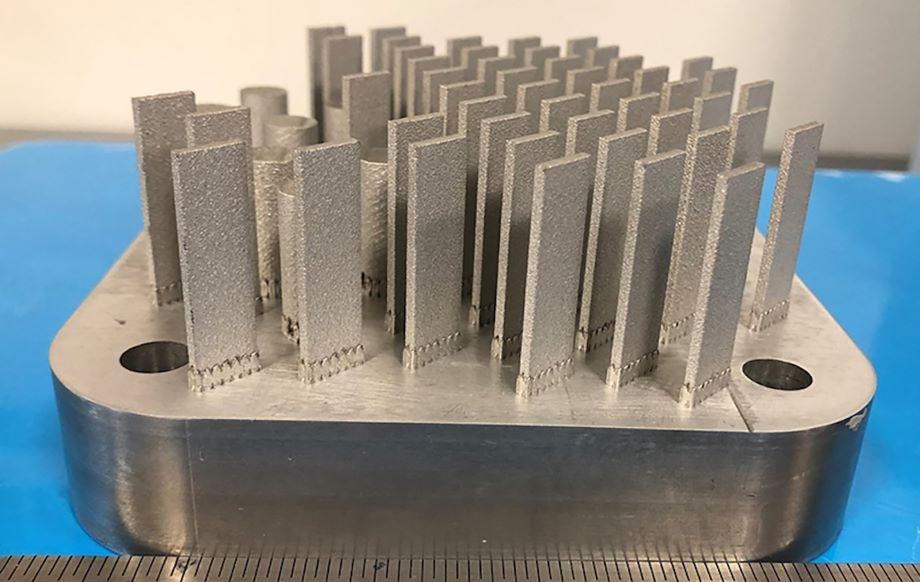

The team spent the first two years learning how to fabricate an Al alloy that was free from cracking. After careful analyses of the extensive experiments, the team thought that large residual stress might be the cause of cracking. “At that moment, a thought came to our minds,” Zhang said. “Could we design a support structure as a cushion to relax the residual stress?” Support structures have been used widely in the AM industry, mostly for easy removal of the printed parts from the build plate. “Using the support to relieve residual stress and improve printability proved to very effective,” Zhang continued. “Having solved the cracking issue, we were able to successfully print high-strength Al alloys with the mechanical properties we were hoping for.”

Discover the Benefits of ASME Membership

The intermetallics have crystal structures with low symmetry and are known to be brittle at room temperature. However, Zhang’s method forms the transitional metal elements into colonies of nanoscale, intermetallic lamellae that aggregate into fine rosettes. The nanolaminated rosettes can largely suppress the brittle nature of intermetallics.

“Also, the heterogeneous microstructures contain hard nanoscale intermetallics and a coarse-grain aluminum matrix, which induces significant back stress that can improve the work hardening ability of metallic materials,” Zhang said. “AM using a laser can enable rapid melting and quenching, thus introducing nanoscale intermetallics and their nanolaminates into the aluminum.”

More For You: New Approach Cuts Manufacturing Time for 3D Parts

The research team then conducted macroscale compression tests, micropillar compression tests, and post-deformation analysis on the Purdue-created aluminum alloys.

During the macroscale tests, the alloys revealed a combination of prominent plastic deformability and high strength, more than 900 MPa. “The micropillar tests displayed significant back stress in all regions, and certain regions had flow stresses exceeding one gigapascal,” Zhang said.

One of the biggest surprises was that a simple support structure can largely reduce cracking in AM alloys. Such a finding may have widespread applications for a variety of other high-strength Al alloys that are vulnerable to cracking—for example, developing a suite of high-strength AM Al alloys for various manufacturing applications.

More on AM: 3D-Printed Fabric Hardens and Softens on Command

This research illustrates how transition-metal additions can benefit the 3D printing of Al alloys by dramatically improving mechanical strength.

The next research steps are two-fold: explore the high-temperature mechanical properties of the alloy, which has great strength at elevated temperatures, and explore other customized chemistries for AM high-strength Al alloys.

“We believe that the classical thermodynamics cannot successfully predict the phases observed in AM alloys,” Zhang said. “Hence it is essential to explore the influence of other intermetallic phases that could be used in AM alloys to improve their mechanical performance.”

Mark Crawford is a technology writer in Corrales, N.M.

There is new hope, however, for creating even stronger aluminum alloys that do not crack and are commercially viable. Materials engineers at Purdue University have created a process for making ultra-strong aluminum alloys that are suitable for AM. These alloys show ultra-high strength (exceeding 900 megapascals) which is much higher than most AM Al alloys, as well as plastic deformability.

Counter-intuitive thinking

The research team—Haiyan Wang and Xinghang Zhang, both professors of materials engineering at Purdue University and Anyu Shang, a materials engineering graduate—has pursued high-strength printable Al alloys for four years. Additively manufactured, high-strength Al alloys generally suffer from hot tearing and cracking. “Our goal,” Zhang said, “has been to develop printable crack-free,-yet-strong, Al alloys. Transition metal elements, such as Fe, Co, and Ni have been largely avoided in traditional manufacturing of Al alloys because they can form large, brittle intermetallic particles in Al alloys, making them brittle. However, we had also speculated that in AM Al alloys, transition-metal intermetallics could have small nanoscale dimensions that would mitigate cracking issues. Using non-popular transition metal elements for AM Al alloys was definitely a counter-intuitive idea to follow.”

The team spent the first two years learning how to fabricate an Al alloy that was free from cracking. After careful analyses of the extensive experiments, the team thought that large residual stress might be the cause of cracking. “At that moment, a thought came to our minds,” Zhang said. “Could we design a support structure as a cushion to relax the residual stress?” Support structures have been used widely in the AM industry, mostly for easy removal of the printed parts from the build plate. “Using the support to relieve residual stress and improve printability proved to very effective,” Zhang continued. “Having solved the cracking issue, we were able to successfully print high-strength Al alloys with the mechanical properties we were hoping for.”

Discover the Benefits of ASME Membership

The intermetallics have crystal structures with low symmetry and are known to be brittle at room temperature. However, Zhang’s method forms the transitional metal elements into colonies of nanoscale, intermetallic lamellae that aggregate into fine rosettes. The nanolaminated rosettes can largely suppress the brittle nature of intermetallics.

“Also, the heterogeneous microstructures contain hard nanoscale intermetallics and a coarse-grain aluminum matrix, which induces significant back stress that can improve the work hardening ability of metallic materials,” Zhang said. “AM using a laser can enable rapid melting and quenching, thus introducing nanoscale intermetallics and their nanolaminates into the aluminum.”

More For You: New Approach Cuts Manufacturing Time for 3D Parts

The research team then conducted macroscale compression tests, micropillar compression tests, and post-deformation analysis on the Purdue-created aluminum alloys.

During the macroscale tests, the alloys revealed a combination of prominent plastic deformability and high strength, more than 900 MPa. “The micropillar tests displayed significant back stress in all regions, and certain regions had flow stresses exceeding one gigapascal,” Zhang said.

More research ahead

One of the biggest surprises was that a simple support structure can largely reduce cracking in AM alloys. Such a finding may have widespread applications for a variety of other high-strength Al alloys that are vulnerable to cracking—for example, developing a suite of high-strength AM Al alloys for various manufacturing applications. More on AM: 3D-Printed Fabric Hardens and Softens on Command

This research illustrates how transition-metal additions can benefit the 3D printing of Al alloys by dramatically improving mechanical strength.

The next research steps are two-fold: explore the high-temperature mechanical properties of the alloy, which has great strength at elevated temperatures, and explore other customized chemistries for AM high-strength Al alloys.

“We believe that the classical thermodynamics cannot successfully predict the phases observed in AM alloys,” Zhang said. “Hence it is essential to explore the influence of other intermetallic phases that could be used in AM alloys to improve their mechanical performance.”

Mark Crawford is a technology writer in Corrales, N.M.