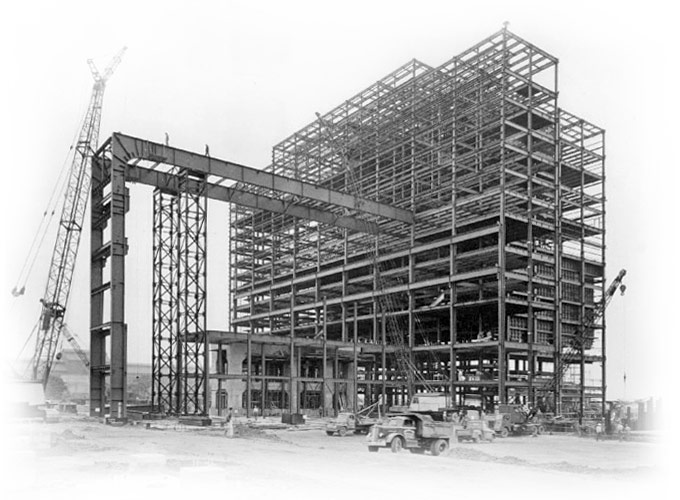

#226 Eddystone Station Unit #1

1960

The second U.S. (earliest extant) supercritical steam-electric generating unit, pioneering significant increases in steam pressure, steam temperature, and unit size

Operated by the Philadelphia Electric Company (PECO), now known as Exelon Corp., Eddystone Station Unit #1 is a 325 MW pulverized-coal-fired plant that pushed the technology of steam-electric generating plants. When built in 1960, engineers sought to make a more efficient plant using higher temperatures and pressures and larger machines. Previous experience at Philo 6 (Zanesville, Ohio, 1957) had demonstrated supercritical steam plants would work, so engineers pushed beyond that frontier to even larger machines and efficiencies. They succeeded, but also discovered a more economically viable generating plant design if pressure and temperature conditions were reduced slightly—and that is how supercritical plants are built today.

Many innovations were implemented along with more widespread application of proven concepts. The steam generator and steam turbine were first-time designs, and the ground covered was new: For example, the steam tables had to be extended into the supercriticial pressure region to develop the design information required for equipment design and sizing. During this phase, the supercritical steam vapor behaved more like a liquid than a vapor, in regard to heat transfer properties. The design phase developed a once-through boiler (no mud drum) that required ultra-pure water, which extracted molecules directly from the metals that it contacted. The turbine design feature new high-speed control valves, unique shaft and inlet seals, and many other innovations. The station also required creep rules to be extrapolated from known values, which proved highly accurate.

Eddystone #1 began, in 1954, as a cooperative agreement by Combustion Engineering Inc. (later known as ABB Combustion Engineering, and now Alstom), Westinghouse Electric Corp.'s Steam Divisions (now Siemens Westinghouse Power Gernation of Orlando, Fla.), and Philadelphia Electric Company (PECO, now Exelon). When designed in 1956-57, this plant consisted of a monotube boiler and cross-compound turbine generator. PECO built a coal-fired 3,600 rpm, tandem compound supercritical-pressure unit of 275 MW capacity (using 25-inch last-row blades) with throttle steam conditions of 5,000 pounds per square inch (psi)/34.5 MPa and 1,200°F/650°C, with two reheats to 1,050°F/565°C. In rapid order, other suppliers of equipment requiring advanced technology were (1) Ingersoll Rand for the boiler feed pumps, (2) Leeds and Northrup for the combustion controls, (3) M.W. Kellogg (now Kellogg Brown and Root, a division of Halliburton Co.) for the high-pressure piping, and (4) Graver Water Conditioning Company (now Graver Technologies) for the water-treatment equipment and demineralizers.

Plaque wording: THIS WAS THE SECOND U.S. SUPERCRITICAL STEAM-ELECTRIC GENERATING UNIT. IT PIONEERED SIGNIFICANT INCREASES IN STEAM PRESSURE, STEAM TEMPERATURE, AND UNIT SIZE. IT WAS BUILT BY A CONSORTIUM OF THE PHILADELPHIA ELECTRIC, WESTINGHOUSE ELECTRIC, AND COMBUSTION ENGINEERING COMPANIES AND, AT THE TIME, WAS THE MOST EFFICIENT IN THE NATION. THE KNOWLEDGE GAINED FROM ITS SUCCESSFUL OPERATION MADE IT THE MODEL FOR TODAY'S HIGH-EFFICIENCY STEAM-ELECTRIC STATIONS.

Landmark Location

One Industrial Highway

Eddystone, PA 19022

Directions

Eddystone #1 is located on the Delaware River at Darby Creek in Delaware County, approximately 1 mile from Chester, Pa.

Visiting Info

Group tours are available by appointment. Plant Manager's office: 610-595-8467.

Ceremony Notes

May 17, 2003; ASME past president Paul Torpey to present the plaque. ASME's Philadelphia Section in Region III (Eastern) sponsored ASME's participation.