Greenhouse Gas Emissions

ASME has played a leading global role in measurement and standard setting for more than 140 years. We also continuously use those same skills to improve ourselves for the good of humanity.

ASME's Emissions Reduction Journey

In pursuit of our position on climate action, ASME has committed to measuring, reporting, and reducing over time all scopes of our greenhouse gas (GHG) emissions.

We believe others will benefit from this window into our emissions-reduction journey and we are committed to shared learning from the solutions we deploy.

What We’ve Accomplished

We have completed measurement of all three scopes of our greenhouse gas emissions for fiscal year 2023, establishing our comprehensive baseline and methodology for measuring future progress and targeting reduction initiatives.

Scope 1 Emissions |

Scope 2 Emissions |

Scope 3 Emissions |

|---|---|---|

|

Direct emissions from owned or controlled sources, such as fuel combustion or the fugitive emissions of refrigerants.

|

Indirect emissions from the generation of purchased electricity, heating, and cooling consumed by the measuring entity.

|

Indirect emissions that occur in our value chain, including both upstream and downstream emissions. For ASME this includes travel and all aspects of event production and logistics.

|

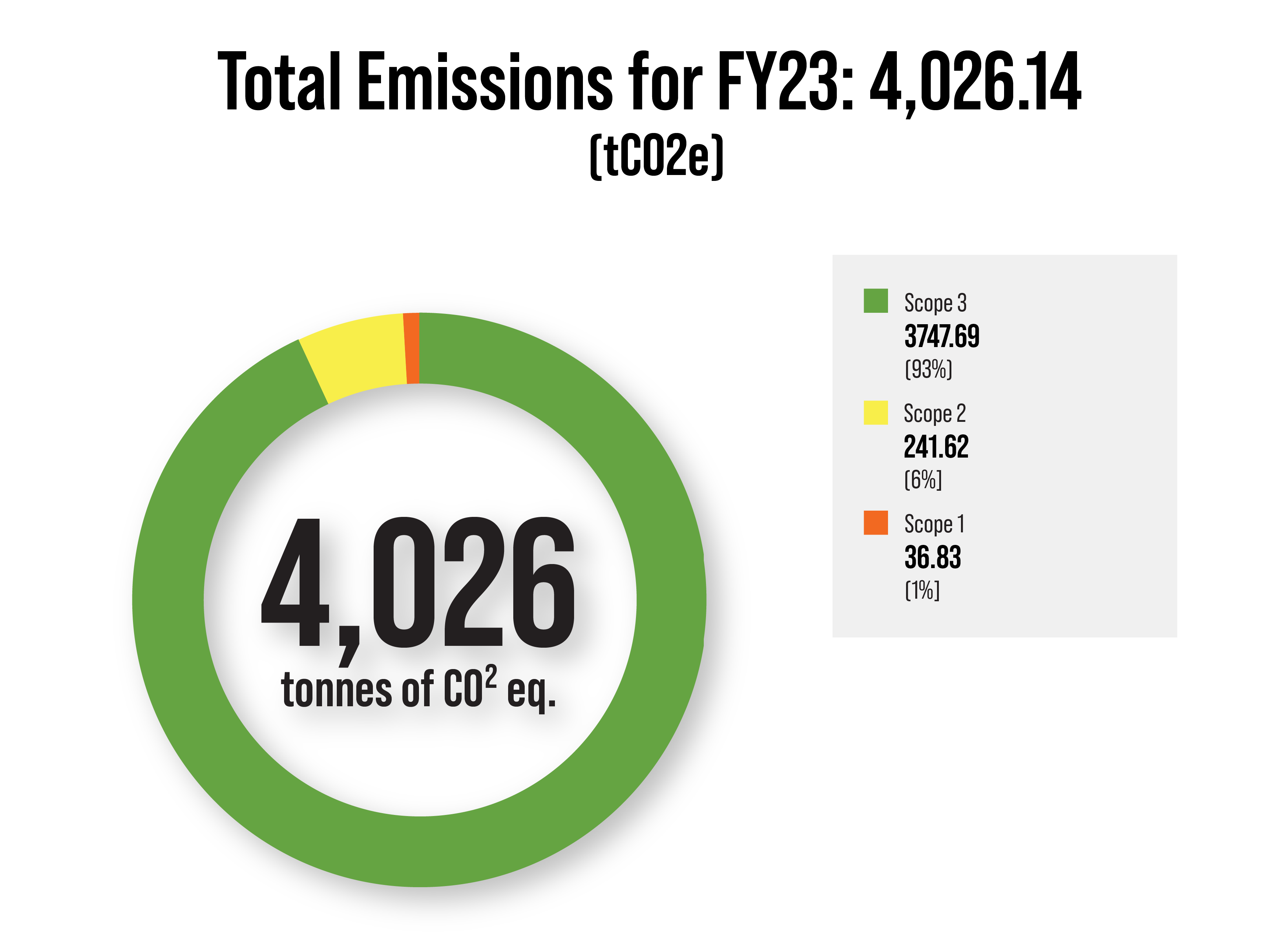

ASME's complete FY2023 emissions baseline totals 4,026.14 tonnes CO2e across all three scopes. With Scope 3 accounting for 93% of our footprint, this comprehensive measurement demonstrates why looking beyond direct operations is essential for meaningful climate action.

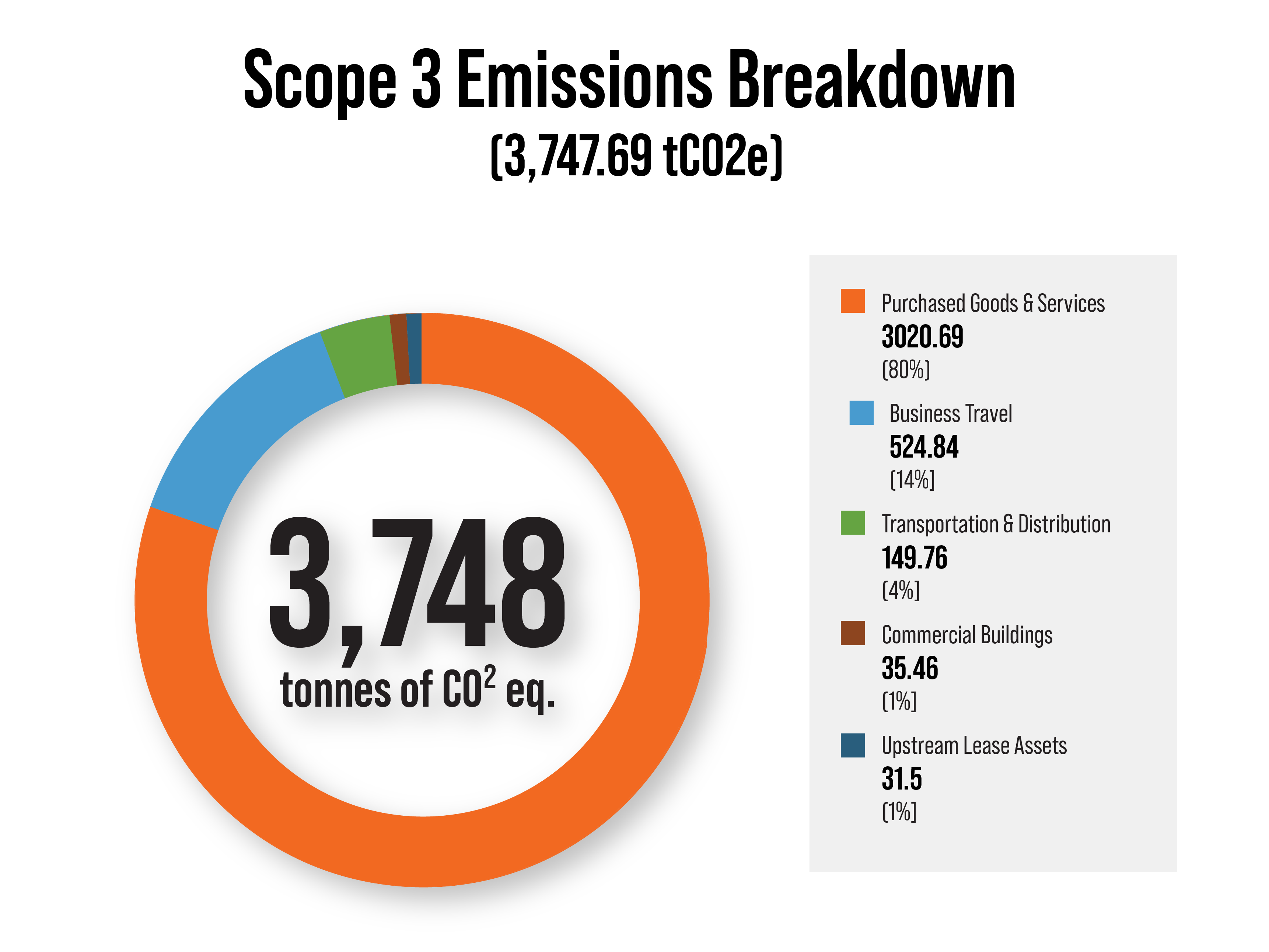

Scope 3 represents 93% of ASME's total emissions at 3,747.69 tonnes CO2e. Purchased goods and services dominate at 80.6%, followed by business travel (14%), transportation/distribution (4%), and other categories (1.4%). This breakdown reveals clear priorities for our reduction strategy.

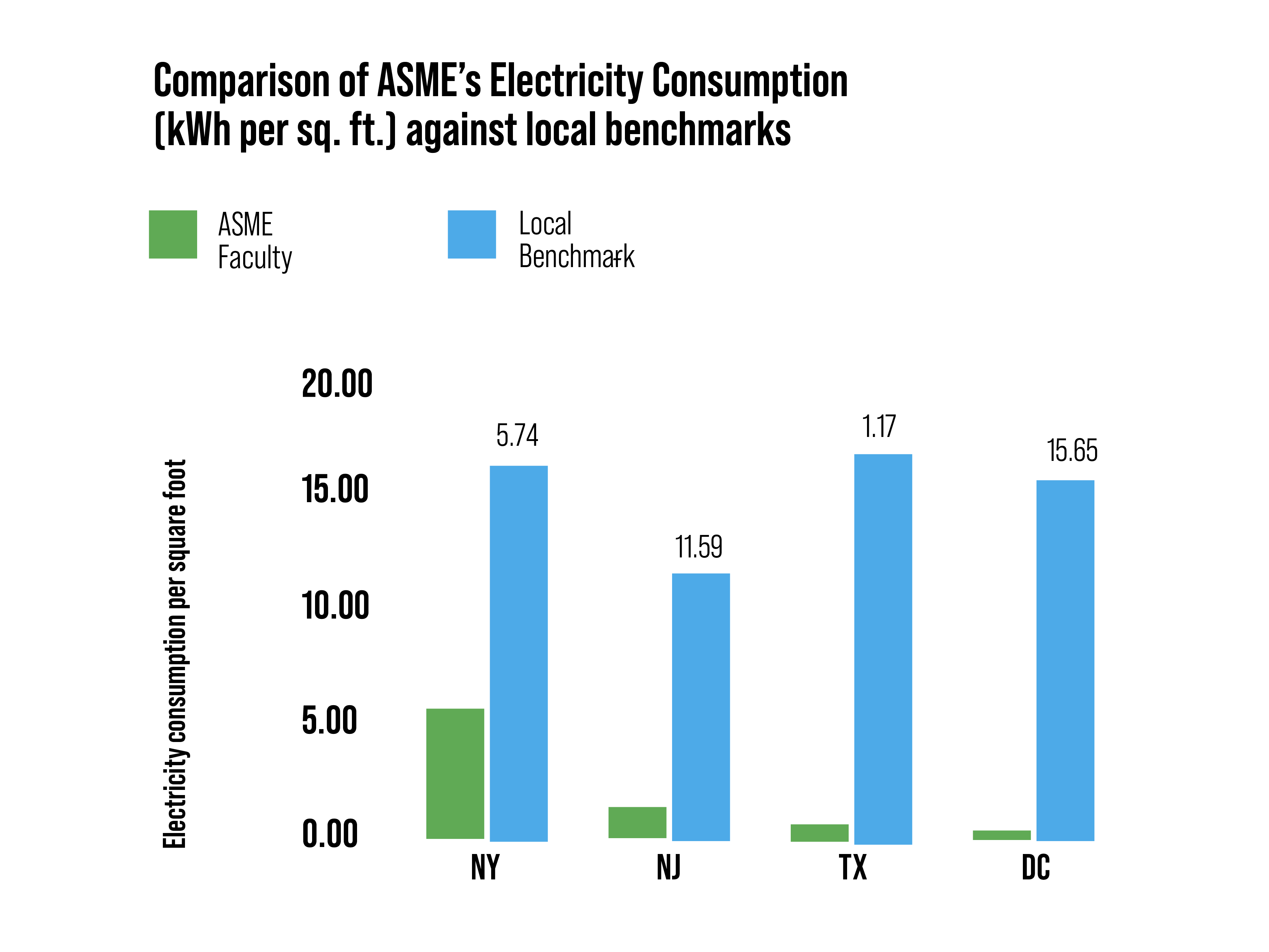

ASME's purchased electricity, a Scope 2 emission, is significantly lower than tenants utilizing similar office spaces in the four U.S. markets where ASME has leased facilities and limited direct control of our emissions.*

*Local benchmark data was only available for US office locations

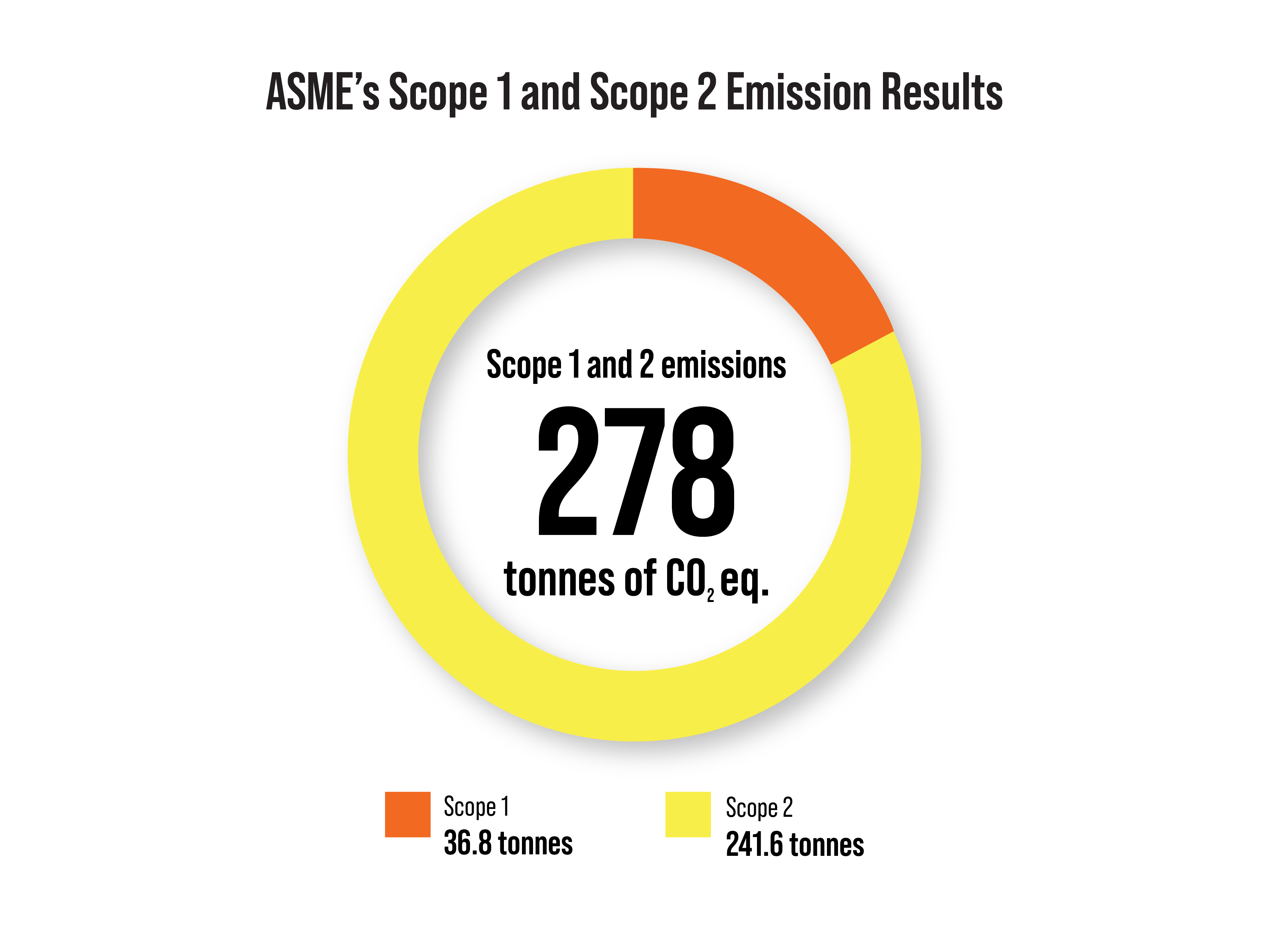

ASME's operational emissions total 278 tonnes CO2 equivalent - Scope 2 purchased electricity and Scope 1 direct emissions. These represent just 5.6% of ASME's total carbon footprint, demonstrating strong operational efficiency with emphasizing the need to address larger Scope 3 supply chain impacts.

Next Steps & Timeline

|

Q4 2025 |

2026 |

2026+ |

|---|---|---|

|

Strategy Development

|

Implementation Phase

|

Continuous Improvement

|