3D Printing Creates Electronic Fabric

3D Printing Creates Electronic Fabric

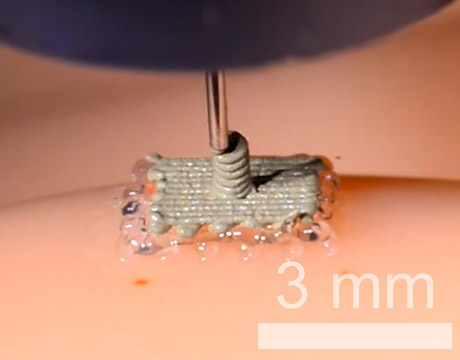

A one-of-a-kind 3D printer can print touch sensors directly on a model hand. Image: Shuang-Zhuang Guo and Michael McAlpine / University of Minnesota

Engineers at the University of Minnesota have developed a one-of-a-kind printer that produces a tiny swatch of what they call stretchable electronic fabric. The fabric—a cube about as big as a peppercorn—is studded with embedded sensors and may set the stage for robots with a sense of touch or humans who have enhanced prosthetic printed directly on their fingertips.

The research team spent about a year tinkering with materials and fabrication before perfecting their printer, which uses four alternating syringe-like nozzles to squeeze out strands of specialized inks in rows the width of human hairs.

The skin consists of a base layer of silicone, top and bottom electrodes made of a conducting ink, and a coil-shaped pressure sensor. A sacrificial layer that holds the top layer in place while it sets eventually washes away.

Significantly, the flexible inks are printed and cured at room temperature, eliminating a major obstacle to affixing these tags to the human body. Conventional 3D printing is too hot, and the objects too hard when they set, to be printed directly onto skin.

“We set out to advance the technology of 3D printing,” said Michael McAlpine, associate professor of mechanical engineering and leader of the research team. “3D printed objects have limited functionality because they are rigid plastics. What we can do here is print a stretchable electronic device on a curved surface like a finger. We first 3D scan a model finger and conformal print electronics on the surface.”

Though they have yet to use human skin, McAlpine’s team has printed a device on the finger of a model human hand. And one of the tactile sensors laminated to a student’s wrist detected and measured his pulse in real time as he went running.

“Because of the versatility of our tools, you can imagine printing many kinds of electronic devices all over the body,” McAlpine said. By exploring a diverse palette of soft, nanoscale materials, he envisions printing different types of sensors on skin for, among other purposes, health monitoring, or for soldiers in the field to detect poison gas or explosives.

One advantage of the team’s innovation is that “the manufacturing is built into the process,” McAlpine said. “Indeed, the 3D printer is a manufacturing tool that can be made portable,” he continued, “and perhaps be carried around in a backpack, to print electronics on the fly.”

In the near-term, the team hopes to use the stretchable devices to conform to the geometry of robots used in minimally invasive surgery, giving them a sense of touch. Currently surgeons rely solely on cameras.

“In the future it would make the surgery more precise to have tactile, or haptic, feedback to these surgical tools,” McAlpine said, “because right now you’re basically just looking into a TV screen.” Read the latest issue of the Mechanical Engineering Magazine.

Indeed, the 3D printer is a manufacturing tool that can be made portable, and perhaps be carried around in a backpack, to print electronics on the fly.Prof. Michael McAlpine, University of Minnesota

.png?width=854&height=480&ext=.png)