5 Feedstocks for Biomass Energy Production

5 Feedstocks for Biomass Energy Production

Biological sources can provide fuel without net carbon emissions. Here are five ways to grow your own power.

Experts talk about the ongoing energy transition away from fossil fuels such as coal and petroleum to wind, solar, geothermal, and nuclear power, which can provide energy without producing carbon emissions. More than 150 years ago, however, industry made a previous transition toward fossil fuels, leaving behind fuels made from wood and other biomass. And little wonder: Compared to biomass, fossil fuels are more energy dense and can be mined in much greater volumes than what can be grown in fields and forests.

Biomass never went away entirely. According to the Energy Information Administration, biomass accounted for around 5 percent of primary energy consumption in the United States in 2023. And worldwide, bioenergy provides up to 10 percent of energy consumed, according to the International Renewable Energy Agency. While in many parts of the world, biomass is used directly as a heating or cooking fuel, processed biomass can be converted to liquid fuel to supplement or replace petroleum.

Just as biological material is wildly different, so too can the feedstocks for biofuels come in various forms. Here are five major feedstocks for producing biofuels.

Wood is still used today for cooking and heating. Nearly 2 million U.S. households rely on a wood-burning stove as their primary heat source, and another 8.8 million use a stove or fireplace as a supplemental heat source. Some thermal power plants burn wood as the primary fuel or as an addition to coal to reduce the plants’ net carbon emissions. Around the world, more than 2 billion people burn wood or other solid fuel for cooking, often in open hearths, which contributes to high levels of indoor air pollution.

To make ethanol, corn must be fermented. In much the same process that produces alcoholic beverages, soaked corn kernels are acted on by yeast to turn their sugars and starches into ethanol. While ethanol is not as energy dense as gasoline, it burns more completely than gasoline (due to the ethanol molecule possessing oxygen atoms). That helps reduce pollution from the tailpipe. Typically, the ethanol content of gasoline sold in the U.S. is 10 percent.

To make ethanol, corn must be fermented. In much the same process that produces alcoholic beverages, soaked corn kernels are acted on by yeast to turn their sugars and starches into ethanol. While ethanol is not as energy dense as gasoline, it burns more completely than gasoline (due to the ethanol molecule possessing oxygen atoms). That helps reduce pollution from the tailpipe. Typically, the ethanol content of gasoline sold in the U.S. is 10 percent.

More than a third of the corn harvested in the U.S. is turned into biofuel. That’s controversial, as some activists will argue the cropland used to grow biofuel would be better served feeding people, while others contend that, given the low energy efficiency of photosynthesis, it would be better to cover those acres with photovoltaic panels.

More on Biofuels: Refueling the Engine

Dried bagasse can be used directly as fuel, with many sugar mills operating bagasse-fired power plants to run their facilities. In the late 1970s, Brazil began an ambitious project to produce ethanol by fermenting bagasse as a way to supplement expensive imported oil. Since 1977, auto fuel in Brazil has been made up of at least 10 percent ethanol, reaching as high as 27 percent ethanol depending on the price of oil. While some vehicles are powered by straight ethanol, biofuel production was never high enough for the country to convert the entire fleet.

In many ways, using bagasse as a feedstock for ethanol production is more sustainable than corn. After all, bagasse is essentially agricultural waste, while corn is a primary crop. Researchers are developing methods for producing more advanced fuels from bagasse, though none have broken through commercially.

While starches and sugars are fermented by yeast, fats and oils, or lipids, are removed from feedstock through physical and thermal means. (For some applications, cooking oil is recycled from restaurants.) Producing fuel from these lipids involves chemical reactions with alcohol and catalysts, plus a purification step to remove soapy byproducts.

Learn about Sustainable Aviation Fuel: Fly the Climate-Friendly Skies

Interest in a renewable alternative to petroleum dates back more than 100 years. In fact, the first diesel engine operated on peanut oil during a demonstration in 1893. While biodiesel fuel is available in certain markets, the most promising energy application for plant oil may be as a feedstock for so-called sustainable aviation fuel, where the oil is converted to kerosene to burn in jet engines.

More recently, manure and other biological waste haave been the feedstock for digesters that rely on microbes to digest organic matter and produce methane or hydrogen. Those combustible gases can replace fossil fuels directly. (The undigested residual makes for good fertilizer.)

Based on Your Interests: Optimized Electrodialysis for Wastewater

According to writer Lina Zeldovich, the first biodigesters appeared 3,000 years ago, but the first systems to turn human sewage into biogas weren’t built until the start of the 20th century. They are still rare, but New York City now has one at a sewage treatment plant in Brooklyn. Considering that more than 350 billion cubic meters of wastewater is produced by humanity each year, using human waste to produce fuel could be a promising energy source.

Jeffrey Winters is editor in chief of Mechanical Engineering magazine.

Biomass never went away entirely. According to the Energy Information Administration, biomass accounted for around 5 percent of primary energy consumption in the United States in 2023. And worldwide, bioenergy provides up to 10 percent of energy consumed, according to the International Renewable Energy Agency. While in many parts of the world, biomass is used directly as a heating or cooking fuel, processed biomass can be converted to liquid fuel to supplement or replace petroleum.

Just as biological material is wildly different, so too can the feedstocks for biofuels come in various forms. Here are five major feedstocks for producing biofuels.

Wood

When humans first tamed fire hundreds of thousands of years ago, they needed something to burn. That something was wood, which became humanity’s first fuel. Wood has many advantages as a fuel. It is an easy-to-store solid. It is relatively easy to ignite. It is stable enough to use long after it has been harvested. And it can be broken into small chunks to provide only as much energy as needed. One of America’s earliest breakthrough inventions, the cast-iron Franklin stove, was created to use wood more efficiently.Wood is still used today for cooking and heating. Nearly 2 million U.S. households rely on a wood-burning stove as their primary heat source, and another 8.8 million use a stove or fireplace as a supplemental heat source. Some thermal power plants burn wood as the primary fuel or as an addition to coal to reduce the plants’ net carbon emissions. Around the world, more than 2 billion people burn wood or other solid fuel for cooking, often in open hearths, which contributes to high levels of indoor air pollution.

Corn

Corn is a widely versatile crop, used directly as food, fed to animals, or processed into a variety of base-level food ingredients. Since the 1980s, corn has also been a feedstock for the production of ethanol, a supplemental fuel for automobiles in the U.S.

Bioprocessing Equipment Overview

Learn how this ASME BPE Standard has improved the manufacturing practices of the bioprocessing and pharmaceutical industries.

More than a third of the corn harvested in the U.S. is turned into biofuel. That’s controversial, as some activists will argue the cropland used to grow biofuel would be better served feeding people, while others contend that, given the low energy efficiency of photosynthesis, it would be better to cover those acres with photovoltaic panels.

Bagasse

While it is a byproduct rather than a crop, bagasse is an important source of biomass energy in some parts of the world. Bagasse is the fibrous pulp that remains after sugarcane is pressed for juice; roughly, for every 1,000 pounds of sugarcane, 300 pounds of fiber are left behind, though as much as half that weight is moisture.More on Biofuels: Refueling the Engine

Dried bagasse can be used directly as fuel, with many sugar mills operating bagasse-fired power plants to run their facilities. In the late 1970s, Brazil began an ambitious project to produce ethanol by fermenting bagasse as a way to supplement expensive imported oil. Since 1977, auto fuel in Brazil has been made up of at least 10 percent ethanol, reaching as high as 27 percent ethanol depending on the price of oil. While some vehicles are powered by straight ethanol, biofuel production was never high enough for the country to convert the entire fleet.

In many ways, using bagasse as a feedstock for ethanol production is more sustainable than corn. After all, bagasse is essentially agricultural waste, while corn is a primary crop. Researchers are developing methods for producing more advanced fuels from bagasse, though none have broken through commercially.

Plant and animal oils

The word “petroleum” quite literally means rock oil. Oils from plants and animals were known long before drillers started producing oil from underground formations. Now, biologically formed oils are seen by some as a way to produce carbon-neutral replacements for diesel and jet fuel.While starches and sugars are fermented by yeast, fats and oils, or lipids, are removed from feedstock through physical and thermal means. (For some applications, cooking oil is recycled from restaurants.) Producing fuel from these lipids involves chemical reactions with alcohol and catalysts, plus a purification step to remove soapy byproducts.

Learn about Sustainable Aviation Fuel: Fly the Climate-Friendly Skies

Interest in a renewable alternative to petroleum dates back more than 100 years. In fact, the first diesel engine operated on peanut oil during a demonstration in 1893. While biodiesel fuel is available in certain markets, the most promising energy application for plant oil may be as a feedstock for so-called sustainable aviation fuel, where the oil is converted to kerosene to burn in jet engines.

Manure

The ultimate waste product, manure has often been collected and burned when other fuels were unavailable. Animals that eat grasses, such as cattle and bison, produce fibrous dung that is high in carbon.More recently, manure and other biological waste haave been the feedstock for digesters that rely on microbes to digest organic matter and produce methane or hydrogen. Those combustible gases can replace fossil fuels directly. (The undigested residual makes for good fertilizer.)

Based on Your Interests: Optimized Electrodialysis for Wastewater

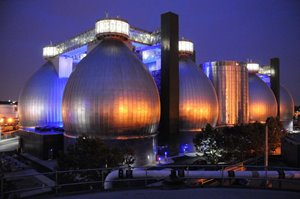

According to writer Lina Zeldovich, the first biodigesters appeared 3,000 years ago, but the first systems to turn human sewage into biogas weren’t built until the start of the 20th century. They are still rare, but New York City now has one at a sewage treatment plant in Brooklyn. Considering that more than 350 billion cubic meters of wastewater is produced by humanity each year, using human waste to produce fuel could be a promising energy source.

Jeffrey Winters is editor in chief of Mechanical Engineering magazine.

.png?width=854&height=480&ext=.png)